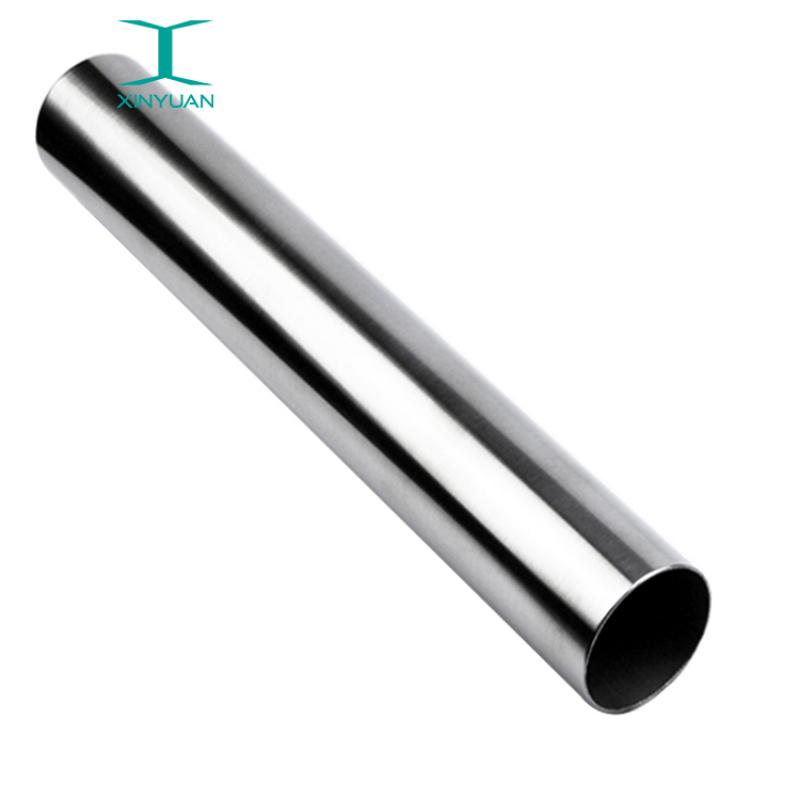

Product SpecificationUnit Pipe Length3 meter, 6 meter, 9 meter, 18 meterMaterialStainless SteelProduct DescriptionGradeTensileUltimate/MinYield/MinElongation/Min-KSIMPAKSIMPA%304755153020535304L704852517035These grades of austenitic stainless steels are the most versatile and widely used stainless steels.

Contacter maintenant

304 stainless steel is a common stainless steel material, density of 7.93 g/cm³, the industry is also known as 18/8 stainless steel.

Contacter maintenant

304 is a universal stainless steel, which is widely used in the manufacture of equipment and parts requiring good comprehensive properties (corrosion resistance and formability). To maintain the corrosion resistance inherent in stainless steel, the steel must contain at least 18% chromium and at least 8% nickel.

Contacter maintenant

Mirror Polished Seamless Stainless Steel1.Not easily rust, acid resistance and corrosion resistance;2.Widely used in light industry,heavy industry, daily necessities and the decoration industry;3.Large and stable supplies, long-term supplies;4.Prompt delivery, rich exporting experience.Material304:0cr18ni9, 0cr17ni8201:1cr17mn6ni5n,1cr13mn9ni1n316:0cr17ni12 or as customer's requestSize(round pipe)9.5, 12.7, 15.9, 17, 18, 19.1, 20, 21, 22.2, 23, 25.4, 28, 318, 35,60, 63.5, 73,

Contacter maintenant

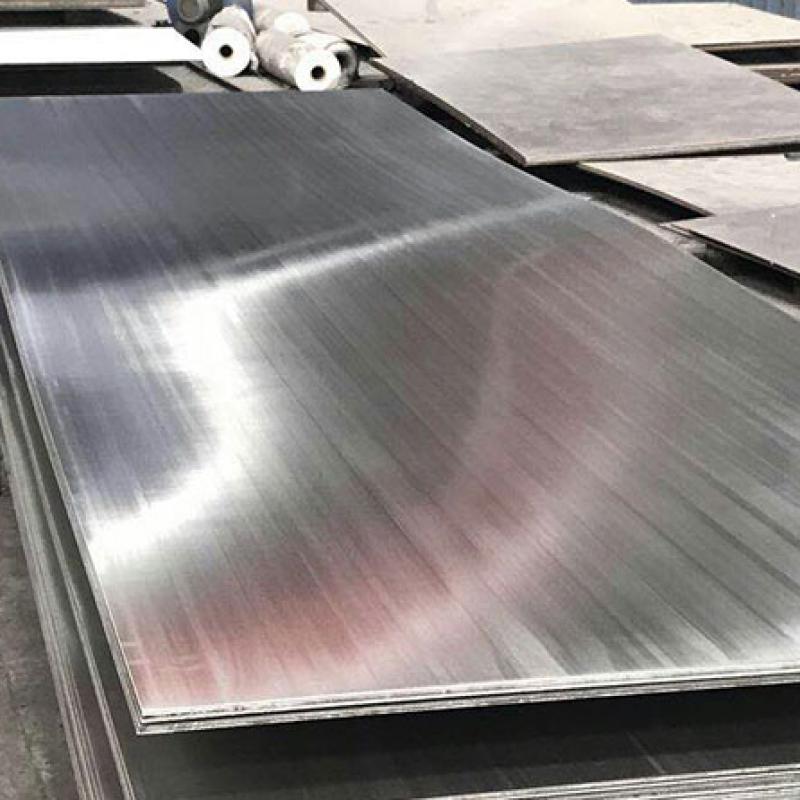

OverviewStainless Steel Sheet Grade 304 is known to be the most widely used and flexible austenitic form of stainless steel. It contains 8% nickel and 18% chromium, making it ultra resistant to corrosion and oxidation.It is also highly durable and can be fabricated with ease.

Contacter maintenant

304 304L Stainless Steel304 is a variation of the basic 18-8 grade, Type 302, with a higher chromium and lower carbon content. Lower carbon minimizes chromium carbide precipitation due to welding and its susceptibility to intergranular corrosion. In many instances, it can be used in the ”as-welded“ condition, while Type 302 must be annealed in order to retain adequate corrosion resistance. Type 304L is an extra low-carbon variation of Type 304 with a 0.03% maximum carbon content that eliminates carbide precipitation due to welding.

Contacter maintenant

Grade 316 is also primarily composed of iron, and again contains significant amounts of nickel and chromium¡ª10-14% and 16-18%, respectively¡ªand small amounts of carbon, manganese, molybdenum, and silicon.

Contacter maintenant

304 304L Stainless Steel304 is a variation of the basic 18-8 grade, Type 302, with a higher chromium and lower carbon content. Lower carbon minimizes chromium carbide precipitation due to welding and its susceptibility to intergranular corrosion. In many instances, it can be used in the ”as-welded“ condition, while Type 302 must be annealed in order to retain adequate corrosion resistance. Type 304L is an extra low-carbon variation of Type 304 with a 0.03% maximum carbon content that eliminates carbide precipitation due to welding.

Contacter maintenant

430 stainless steel is a type of ferritic stainless-steel that consists of chromium, which gives it its corrosion-resistant properties. the primary alloying element in 430 stainless-steel is chromium, generally starting from 16 to 18 percentage. it additionally has a low carbon content material, which improves its weldability.430 stainless-steel bars are generally utilized in various packages due to their desirable mixture of corrosion resistance, formability, and affordability.

Contacter maintenant

Grade 310s Stainless Steel is the standard "18/8" stainless; it is the most versatile and most widely used stainless steel, available in a wider range of products, forms and finishes than any other.

Contacter maintenant

304 (UNS S30400, 1.4301) stainless steel is a universal stainless steel, it is widely used to make equipment and machine parts that require good comprehensive performance. In order to maintain the inherent corrosion resistance of stainless steel, the steel must contain more than 18% chromium and more than 8% nickel content. 304 stainless steel is a grade of stainless steel produced in accordance with the American ASTM standard.The most important elements in 304 stainless steel are Ni and Cr, but they are not limited to these two elements.

Contacter maintenant

Seamless Stainless Steel Pipe1.Not easily rust, acid resistance and corrosion resistance;2.Widely used in light industry,heavy industry, daily necessities and the decoration industry;3.Large and stable supplies, long-term supplies;4.Prompt delivery, rich exporting experience.Material304:0cr18ni9, 0cr17ni8201:1cr17mn6ni5n,1cr13mn9ni1n316:0cr17ni12 or as customer's requestSize(round pipe)9.5, 12.7, 15.9, 17, 18, 19.1, 20, 21, 22.2, 23, 25.4, 28, 318, 35,60, 63.5, 73, 76.2, 88.9,

Contacter maintenant

Type 309 is an austenitic chromium nickel stainless steel (.08% max carbon).Type 309is employed for parts requiring both corrosion and heat resistance and oxidation resistance up to 2000oF. Strength at elevated temperatures is similar to that of 18-8 Stainless Steels.This alloy posses excellent resistance to oxidation as well as high tensile and creep strengths at elevated temperatures.

Contacter maintenant

304 Stainless Steel PIpe is a universal stainless steel, which is widely used in the manufacture of equipment and parts requiring good comprehensive properties (corrosion resistance and formability). To maintain the corrosion resistance inherent in stainless steel, the steel must contain at least 18% chromium and at least 8% nickel.

Contacter maintenant

The density of 304 stainless steel 7.93 g/cm3 austenitic stainless steel generally used this value 304 chromium content (%) 18--20.304 is equivalent to our 0Cr19Ni9 (0Cr18Ni9) stainless steel 304 stainless steel is a universal stainless steel material, Rust resistance is better than 200 series stainless steel material. High temperature resistance is also relatively good, can be as high as 1000-1200 degrees. 304 stainless steel has excellent corrosion resistance and corrosion resistance between grains.

Contacter maintenant

Stainless Steel Round Tube Material304:0cr18ni9, 0cr17ni8201:1cr17mn6ni5n,1cr13mn9ni1n316:0cr17ni12 or as customer's requestSize(round pipe)9.5, 12.7, 15.9, 17, 18, 19.1, 20, 21, 22.2, 23, 25.4, 28, 318, 35,60, 63.5, 73, 76.2, 88.9, 101.6, 114.3, 127, 133, 159, 168, 219 mm or customizedSize (square pipe)10×10,12×12,18×18,23×23,38×38,50×50,70×70,100×100,20×10,23×10,24×12,25×13,36×23,40×20,50×20,60×15,75×45,80×60,9

Contacter maintenant

Stainless Steel 304L FlangesStainless Steel 304L Flanges has a minimum of 18% chromium and 8% nickel. Type SS 304L Blind FLanges(BLRF) has a Carbon maximum is 0.035. Stainless Steel 304L Pipe Flanges is the standard "18/8 stainless" that is commonly found in Industrial Flanges and applications. 304L Stainless Steel Blind Flange is the most versatile and widely used alloy flange. The ultimate tensile strength (UTS) of SS 304L Spectacle Blind Flange is roughly~515 Mpa, 304L having a 0.2% yield strength of~205Mpa.

Contacter maintenant

Austenitic stainless steel refers to stainless steel with an austenitic structure at room temperature. When the steel contains about 18% Cr, 8%-25% Ni, and about 0.1% C, it has a stable austenite structure. Austenitic chromium-nickel stainless steel includes the famous 18Cr-8Ni steel and the high Cr-Ni series steel developed by adding Cr and Ni content and adding Mo, Cu, Si, Nb, Ti and other elements on this basis. Austenitic stainless steel is non-magnetic and has high toughness and plasticity, but its strength is low. It is impossible to strengthen it through phase transformation.

Contacter maintenant

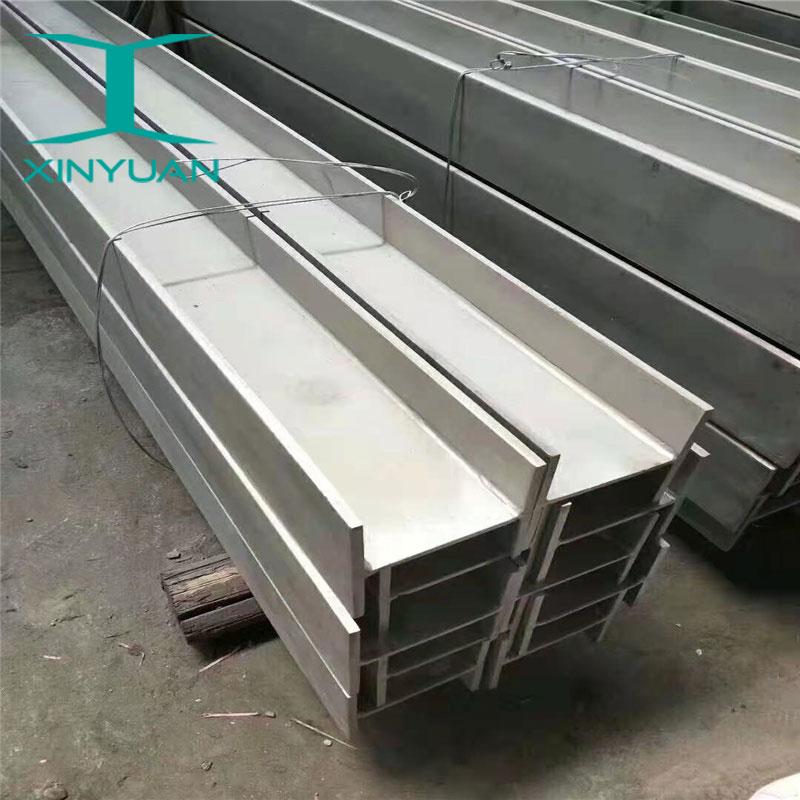

The 304l stainless-steel i-beam is a chromium-nickel grade of metallic. it includes 8 percentage nickel and 18 percent chromium. it's miles a with ease machinable metallic that has remarkable formability and weldability. it has desirable corrosion-resistance and is even able to face up to intergranular corrosion, which could arise after welding or stress relieving. as it has a low content material of carbon, it could be accurately utilized in maximum welded construction operations that use temperatures no better than 800 tiers f.

Contacter maintenant

304 Stainless Steel CoilWith its chromium-nickel content material and low carbon, 304 Stainless Steel Coil is the most versatile and broadly used of the austenitic stainless steels. Occasionally referred to as "18-8," 304 Stainless Steel Coil has higher corrosion resistance than Type 301 or 302 and provides high-quality drawing and forming characteristics.

Contacter maintenant

The 304L Stainless Steel Flat Bar is an austenitic metal that is made up of 18 percent chromium and 8 percent nickel. The carbon maximum for this grade of metal is 0.030 percent. This alloy is widely used because of its versatility. It is the most used stainless steel alloy in its family. 304L stainless steel is highly resistant to corrosion, even intergranular corrosion, which is caused by stress relieving or welding. Its low level of carbon makes it ideal for the majority of welded construction operations that use service temperatures that are limited to 800 degrees F.

Contacter maintenant

The Incoloy 901 Nickel Base Alloy Pipe content makes it have better oxidation resistance than standard 18-8 stainless steel, and its oxidation resistance is no less than that of higher grade alloys with temperatures up to 1900 ° f (1038 ° c).1. Fire control system, seawater purification system, hydraulic pressure and perfusion piping system in ocean engineering.2, cellulose pulp production in the bleaching pool.3. Polished rods in corrosive oil Wells.4. Hose system in ocean engineering.5. Pipelines, joints and airflow systems in acid gas production.6.

Contacter maintenant

304 Stainless Steel Wire304 Stainless Steel Wire is a universal motive stainless alloy usually composed of 18% chromium and 8% nickel. 304 Stainless Steel Wire is the most broadly used stainless spring wire due to the fact of its excessive corrosion resistance residences and correct tensile strength. For spring purposes 304 Stainless Steel Wire is normally furnished in the bloodless drawn condition. 304 Stainless Steel Wire has right power at average temperatures. If proper handled after forming they will set much less than most different spring substances at temperatures up to 500ºF.

Contacter maintenant

Many industry will use 420 stainless steel rods, this kind of material with metallic luster, so choose the material production tools or equipment products, prominent on the appearance, the surface of the plate is very smooth, can also be customized according to the actual demand for processing, high plasticity, in the process of installation can tolerate acid and alkaline substances.Product Parameter:ProductStainless Steel BarBase materialstainless steel 200 series,300 series,400 seriesThickness0.40-5.00mmDiameter6-273mmstandardASTM A554/DIN/EN10296-2/JIS G3446,A269,A249,A270,EN10204 3.1Qualit

Contacter maintenant