321 stainless steel of Ti as a stabilizing element exists, but it is also a hot steel, in terms of high temperature is better than 316 l. 321 stainless steel in different concentration and temperature of organic acid and inorganic acid, especially in oxidizing medium has good abrasion resistance, used in the manufacture of the lining of wear resistant acid containers and equipment and pipelines.

Contacter maintenant

Product DescriptionProduct Namestainless steel coilsMaterial(DIN)1.4301/1.4306/1.4541/1.4401/1.4404/1.4571/1.4539/1.4410/1.4833/1.4845Thickness0.3-100mmWidth600mm, 1000mm, 1219mm, 1500mm, 1800mm, 2000mm, 2500mm, 3000mm, 3500mm, etcLength2000mm, 2440mm, 3000mm, 5800mm, 6000mm, etcSurface2B, BA, NO.4, Mirror, Hairline, etcStandardJIS, AISI, ASTM, GB, DIN, EN, AISI, ASTM, DIN, EN, GB, JISGrade201/304/304L/321/316/316L/310S/904L/309S/316Ti/317L/2205/2507, etc.TechniqueCold Rolled,Hot RolledCertificationISO9001, SGS, BV, ISO, CEUsedBuilding Industry Machinery, etc.MOQ1 TonPayment termsL/C at sight

Contacter maintenant

Class: E316HTX-XAWS: A5.22Conforms to Certification: AWS A5.22 ASME SFA A5.22Weld Process: Gas Metal ArcAWS Chemical Composition RequirementsC = 0.04 – 0.08S = 0.03 maxMn = 0.5 – 2.5Cr = 17.0 – 20.0Si = 1.0 maxNi = 11.0 – 14.0P = 0.04 maxMo = 2.0 – 3.0Cu = 0.75 maxApplicationElectrodes of this classification usually are used for welding similar alloys.

Contacter maintenant

SAF 2507 offers high compressive strength, impact strength, low coefficient of thermal expansion and high thermal conductivity.These characteristics are applicable to many structural and mechanical components.SAF 2507 has high impact strength and is not suitable for prolonged exposure to temperatures higher than 570°F, which may reduce toughness.2507 stainless steel composition content.GradeCMnSiPSCrMoNiN2507Min.Max.≤0.03≤1.2≤0.80≤0.035≤0.0224-263-56-80.24-0.32Chemical CompositionENASTM/UNSCNCrNiMoCOMPOMENT11.43013040.0418.18.321.4307304L0.0218.18.331.45413210.0417.39.1Ti0.2441.45503470.0517.5

Contacter maintenant

Stainless steel hexagon barMaterial :SUS201, 202, 301, 303, 304, 304L, 316, 316L, 316F, 321, etcChemical composition of 316 stainless steelC 0.08 or lessSi 1.00 or lessMn 2.00 or lessP 0.035 or lessS 0.03 or lessNi: 10.0 to 14.0Cr: 16.0 to 18.5Mo: 2.0 to 3.01 mainly processing stainless steel bolts and nutsProcessing all kinds of stainless steel industrial parts3 should be 303 with good corrosion resistance and is widely used in coastal buildings to resist wind and seawater.Because 303 has good oxidation resistance, it is widely used in all kinds of machinery in food industry.5 303 is also wid

Contacter maintenant

Ti in 321 stainless steel exists as a stabilizing element, but it is also a heat-strong steel, which is much better than 316L in the aspect of high temperature.321 stainless steel has good abrasion resistance in organic and inorganic acids at different concentrations and temperatures, especially in oxidizing media, and is used for the manufacture of wear-resistant acid containers and wear-resistant equipment lining, conveying pipeline.Product Parameter:StandardASTM A479,ASTM A276,ASTM A484, ASTM A582, ASME SA276, ASME SA484, GB/T1220, GB4226,&n

Contacter maintenant

Our manufacturing facility can customise the coloration, specification and length of the products in keeping with your necessities, and the packaging box can customize the logo and fashion in step with your requirements.

Contacter maintenant

According to the main chemical composition is divided into chromium stainless steel, chromium nickel stainless steel and chromium manganese nitrogen stainless steel; Can also be divided into acid resistant stainless steel and heat resistant stainless steel with performance characteristics; It is usually classified by metallographic structure.

Contacter maintenant

Stainless Steel PipeFormWelded and Seamless in Round.ApplicationFluid & Decorative.Size RangeDN15 – DN600.Grades304/304L & 316/316L.321,309S,310S,347H,2205,2507,254SMO, Wall ThicknessSch 10S, 40S & 80S.FittingsButt Weld, Screwed & Socket Flanges (ANSI, Table E & Table D).ProcessingCut-to-length & polishing.The information provided is for standard stock product and does not encapsulate all available combinations.

Contacter maintenant

Detailed content:Standard:AWS A 5.9YB/T5092Chemical Composition %CMnSiCrNiPSGradeER304≤0.081.0 – 2.5≤ 0.6017 – 198 – 11≤ 0.03≤ 0.03TypeSpool (MIG)Tube (TIG)Specification ( MM )0.8、0.9、1.0、1.2、1.6、2.01.6、2.0、2.4、3.2、4.0、5.0PackageS100/1kg S200/5kgS270,S300/15kg-20kg5kg/box 10kg/box length :1000MMMechanical PropertiesTensile Strength MpaElongation after fracture A(%)≥ 520≥ 30Diameter(MM)0.81.01.21.62.02.53.2Current(A)

Contacter maintenant

Grade 410 belongs to the martensitic family of stainless steel alloys. Its high chromium content, which averages about 11.5 percent of its total composition, gives this stainless steel outstanding resistance to corrosion and excellent durability.

Contacter maintenant

202 stainless steel is one of the 200 series of stainless steel, gb model is 1Cr18Mn8Ni5N. 200 series stainless steel belongs to low nickel high manganese stainless steel, nickel content, manganese content of about 8%, is a section of nickel stainless steel.Chemical composition/%BrandCSiMnPSNiCrMoCuNother202≤0.15≤1.0≤7.5~10.0≤0.060≤0.034.00~6.0017.0~19.0----≤0.25BrandH treatmenteatThe yield strengthMpaTensile strengthMpaModulus of elasticity psiHBSHRBHV2021010~1120Fast cooling≥275≥520≥400000≤207≤95≤218Packaging & Shipping

Contacter maintenant

Superior creep and stress rupture properties are demonstrated by SS 321 Hex Bars in comparison with Stainless Steel 304 Hex Bars and, more specifically, Stainless Steel 304L Hex Bars, which may be considered for use in environments prone to sensitization and intergranular corrosion.

Contacter maintenant

321 stainless steel is a Ni-Cr-Mo type austenitic stainless steel, its properties are very similar to 304, but due to the addition of metal titanium, it has better resistance to grain boundary corrosion and high temperature strength. Due to the addition of metallic titanium, it effectively controls the formation of chromium carbide. Ti in 21 stainless steel exists as a stabilizing element, but it is also a heat-strength steel, which is much better than 316L in high temperature.

Contacter maintenant

321 Stainless Steel Coil321 Stainless Steel Coil and sheet is section of the austenitic household of stainless steel. 321 Stainless Steel Coil is essentially a 304 grade containing a stabilizer of titanium. 321 Stainless Steel Coil is a exact desire for functions the place warmth is an issue. 321 Stainless Steel Coil can be used in purposes up to 900 stages Celsius the place 304 is typically used up to five hundred levels Celsius. 321 Stainless Steel Coil has brilliant forming and welding characteristics.

Contacter maintenant

321 stainless steel flat bar, also known as UNS S32100 and Grade 321, is primarily comprised of 17% to 19% chromium, 12% nickel, .25% to 1% silicon, 2% maximum manganese, traces of phosphorus and sulfur, 5 x (c + n) .70% titanium, with the balance being iron. With regards to corrosion resistance, 321 is equivalent to Grade 304 in the annealed condition and is superior if the application involves service in the 797° to 1652° F range.

Contacter maintenant

Stainless Steel Bar 321 316Stainless steel bar provides excellent tensile strength, high resistance to rust, and high fabrication ability. stainless steel bar is a highly cost-effective and versatile material.

Contacter maintenant

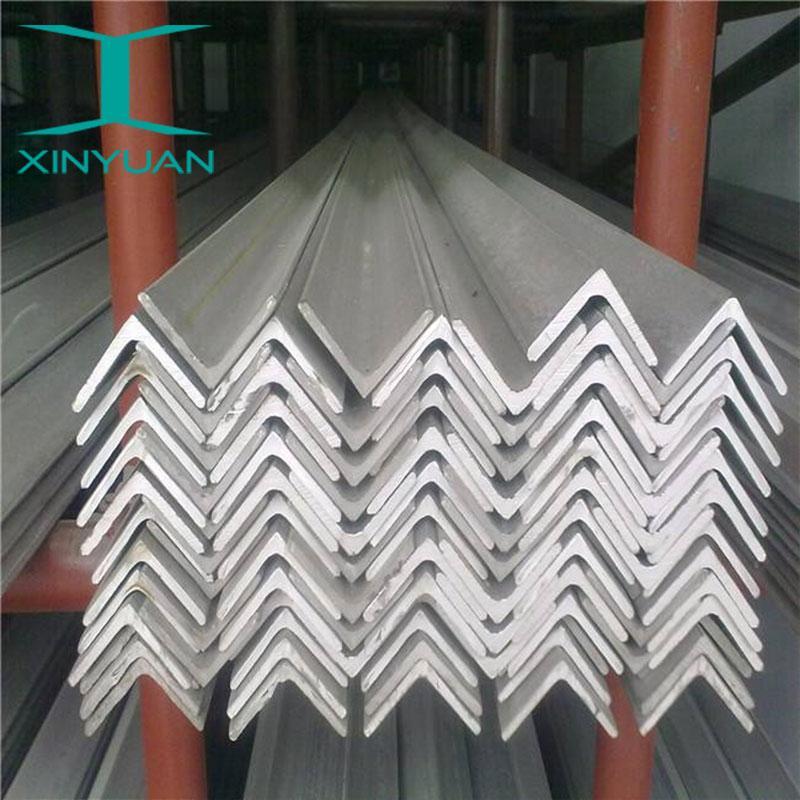

321 Stainless Steel Profile/Angle steel, It is used principally for applications involving welding or sustained elevated temperature operations.

Contacter maintenant

Company ProfileSince its establishment Tianjin Xinyuan Stainless Steel Co., Ltd. has been steadily seeking progress with the care and support of colleagues and customers from all walks of life, and has developed into a comprehensive enterprise integrating stainless steel material processing and sales agents.Main materials: 201, 301, 304 (0Cr18Ni9), 304L (00Cr19Ni10), 321 (1Cr18Ni9Ti), 316 (0Cr17Ni12Mo2), 316L (00Cr17Ni14Mo2), 309S (0Cr23Ni13), 310S (0Cr25Ni20), 904L (00Cr20Ni25Mo4.5Gu) 316 , 317L, 317H, 304H, (SUS304, 321, 316, 310S, etc.). Duplex stainless steel (2205, 2507, 2520).

Contacter maintenant

Austenitic stainless steel refers to stainless steel with an austenitic structure at room temperature. When the steel contains about 18% Cr, 8%-25% Ni, and about 0.1% C, it has a stable austenite structure. Austenitic chromium-nickel stainless steel includes the famous 18Cr-8Ni steel and the high Cr-Ni series steel developed by adding Cr and Ni content and adding Mo, Cu, Si, Nb, Ti and other elements on this basis. Austenitic stainless steel is non-magnetic and has high toughness and plasticity, but its strength is low. It is impossible to strengthen it through phase transformation.

Contacter maintenant

Product Name SS 304 304L 310S 316 316L 321 309S 904L 2205 Stainless Steel Strip Manufacturer Stainless Steel CoilSteel typeAISI 630, AK Steel 17-4PH, UNS 17400JIS SUS630 X5CrNiCU17-04EN 1.4542StandardASTM A564Thickness0.04-10mmWidth5-2000mmFinishingSolution treated + age hardening heat treated ( H900, H1150, H1150D, H1150M, H1075, H1025 etc )Feature of 630High Tensile strength, high hardness after heat treated.Mechanical propertyT.S. (Rm): 1015Mpa, Y.S.

Contacter maintenant

Stainless steel coil beautiful appearance, good surface quality, suitable for all-weather construction, little influence by climate conditions .The main characteristics of stainless steel coil are: strong corrosion resistance, good surface quality, convenient processing, economic and practical.Product Parameter :Chemical composition and mechanical properties of stainless steel coilsGradeChemical Composition (%)Mechanical PerformanceCSiMnPSNiCrMoHardness201≤0.15≤1.005.5/7.5≤0.060≤0.033.5/5.516.0/18.0-HB≤241,HRB≤100, HV≤240304≤0.08≤1.00≤2.00≤0.045≤0.038.0/11.018.0/20.0-HB≤187,HRB≤90,HV≤200316≤0.

Contacter maintenant

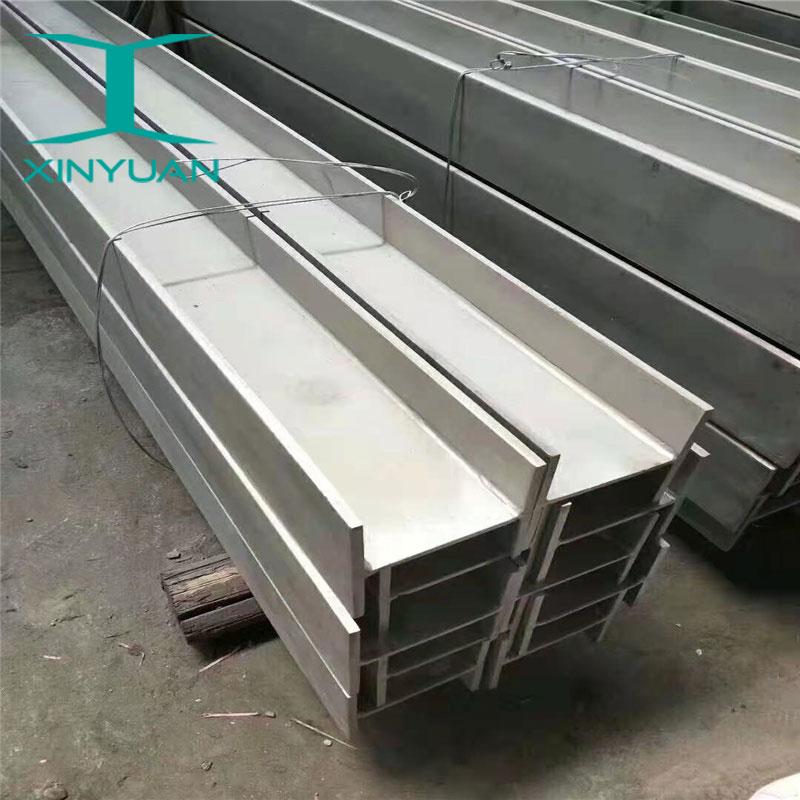

316L Stainless steel channelThe main purpose of hot-rolled stainless steel common channel steel: common channel steel is mainly used in building structures, vehicle manufacturing and other industrial structures, and is often used in conjunction with I-beams.The commonly used stainless steel channel materials for stainless steel production are: 201, 202, 301, 304, 321, 316, 316L, and special materials can generally be customized.316L Stainless steel channel details:Product NameStainless steel channelMaterial201,304,316,321,347h,309s,310s904lThickness1.5mm/1.9mm/2.0mm/2.5mm/2.7mm12GA/14GA/16GA/0

Contacter maintenant

Stainless steel coil: Material: SUS201, 202, 304, 316L, 316Ti, 321, 304L, 441, 444, 436, 439, 430, 409L, 410S, 309S, 310S, 904L, 2205, 2507, etc. Thickness: 0.3-16.0mm, width 1 meter, 1.22 meters, 1.5 meters, 1.8 meters, 2 meters, non-standard can be customized. Stainless steel properties:As a widely used steel, has good corrosion resistance, heat resistance, low temperature strength and mechanical properties; Stamping, bending and other hot workability, no heat treatment hardening phenomenon (use temperature -196℃~800℃). Household products (cl

Contacter maintenant