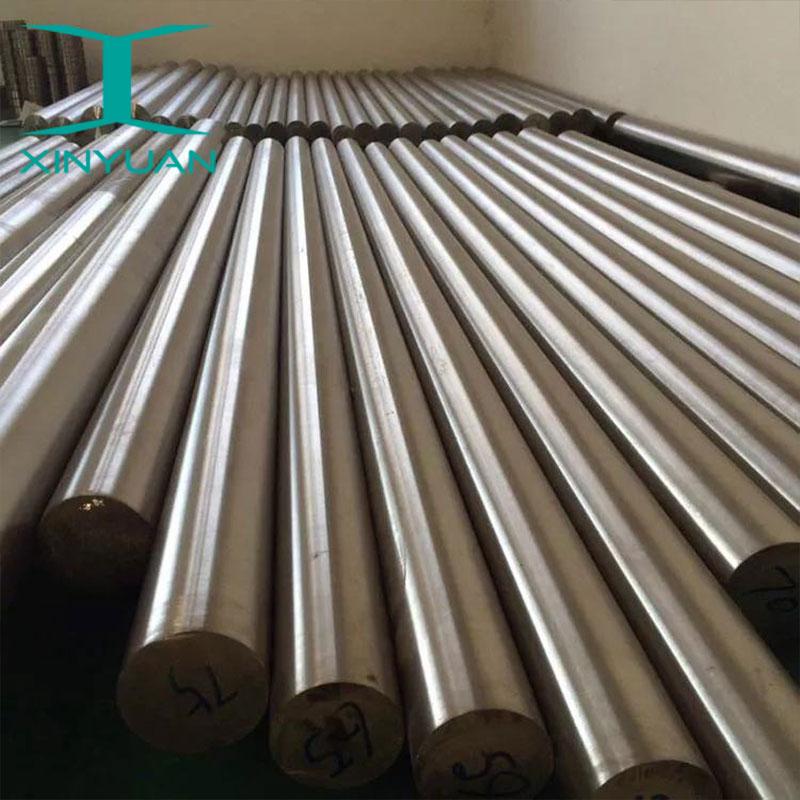

Bars are the most common raw material used by industries in various shapes and sizes, one such shape of the bar is Alloy 926 Round Bar. The most common shapes of Bars are Alloy 926 Round Bar, Alloy 926 Square Bar, Alloy 926 Rectangle Bar, and Alloy 926 Hex Bar.

Contacter maintenant

This alloy has the following properties.1. High resistance to pitting and crevice corrosion in halide media and acidic media containing H2S2. Effective resistance to chloride ion stress corrosion cracking in practical applications3. Excellent corrosion resistance to all kinds of corrosion in the usual oxidizing and reducing environment4. Mechanical properties are improved compared to Cronifer 1925 LC-Alloy 904 L5.

Contacter maintenant

Incoloy 926 nickel-based alloy application areas:1、Fire protection system, seawater purification system, hydraulic and perfusion piping system in marine engineering:2、Bleaching pool in cellulose pulp production;3、Polishing rods in corrosive oil wells:4、Hose system in marine engineering:5、Piping, joints, airflow system in acid gas production, etc;6、Components in flue gas desulfurization system;7、Evaporator, heat exchanger, filter, mixer, etc.

Contacter maintenant

Chemical composition of Incoloy926 nickel base alloyThe content of Cr in nickel-based alloys is usually 14.0-18.0% and the content of nickel is 24.0-26.0%.

Contacter maintenant

Alloy A286 features high strength, oxidation resistance, and corrosion resistance at continuously high temperatures. A286 alloys are heat treatable to achieve a wide variety of grain structures and tensile properties. This grade of A286 is annealed and aged. Applications for Alloy A286 include jet engine components, superchargers, turbine wheels and blades, fasteners, springs, and general high-stress components in petrochemical, aerospace, and oil patch industries.DetailsA286 is an iron-nickel-chromium alloy with additions of molybdenum and titanium.

Contacter maintenant

904L Stainless Steel BarNickel base corrosion resistant alloys have austenite structure. In the state of solid solution and aging treatment, there are intermetallic phases and metal carbonitrides on the austenite matrix and grain boundary of the alloy.Ni Mo alloy is mainly used under the condition of reducing medium corrosion.

Contacter maintenant

C276 Nickel Base Alloy Bar Hastelloy C-276 CharacterThe key elements influencing corrosion resistance of this fabric are the control of impurity S,P, gascontent O,N and key factors C,Si, and so forth.It depends on the manage of manufacturing procedure, which include thepreference of heating temperature and heat maintenance time of forging, such as the assure of forgingratio, inclusive of the assure of strong answer remedy, and so on.Product Parameter:2.Chemical compositionCSMnPSNiCrMoFeCoWVMin14.515.04.03.0Max0.010.081.00.040.03Mar

Contacter maintenant

Incoloy 330 is a nickel-ferrichrome austenite alloy.specifically designed for antioxidant and carburizing effects in high-temperature environments.Product Parameter:Prdouct NameNickel Alloy BarGradeHastelloy: Hastelloy B / B-2/B-3/C22/C-4/S/ C276/C-2000/G-35/G-30/X/N;Inconel: Inconel 100/600/601/602CA/617/625713/718738/X-750,Carpenter 20;Incoloy: Incoloy 800/800H/800HT/825/925/926;Monel: Monel 400/K500Nimonic: Nimonic 75/80A/90 ;OuterDiameter (OD)Peeling Bar: 16~180mmCold Drawn Bar: 4.76~120mm (All sizes can be customized)Forged Bar: 180~400mmLengthCustomizedApplicationAuto, turbines

Contacter maintenant

HASTELLOY C-2000 The most versatile performanceCorrosion-resistant alloy with excellent uniform corrosion resistance in both oxidizing and reducing environments.Product Parameter:Prdouct NameNickel Alloy BarGradeHastelloy: Hastelloy B / B-2/B-3/C22/C-4/S/ C276/C-2000/G-35/G-30/X/N;Inconel: Inconel 100/600/601/602CA/617/625713/718738/X-750,Carpenter 20;Incoloy: Incoloy 800/800H/800HT/825/925/926;Monel: Monel 400/K500Nimonic: Nimonic 75/80A/90 ;OuterDiameter (OD)Peeling Bar: 16~180mmCold Drawn Bar: 4.76~120mm (All sizes can be customized)Forged Bar: 180~400mmLengthCustomizedApplicationAuto, turb

Contacter maintenant

Monel K500 Round BarMonel K500 Round Bar is a age hardened alloy, whose basic composition makeup consists of elements like Nickel&Copper. Which combines the corrosion resistance of Alloy 400 with the high strength, fatigue resistance and erosion resistance.Monel K500 is a nickel-copper alloy, precipitation hardenable through additions of aluminium and titanium. Monel K500 has excellent corrosion resistant characteristics.

Contacter maintenant

Alloy 625 (UNS NO6625) is used in combustion system transition bushings, propeller blades, seals, fasteners, pumps, turbine rings, heat exchanger tubes, reaction vessels, distillation towers, heat exchangers and valves.Product Parameter:Prdouct NameNickel Alloy BarGradeHastelloy: Hastelloy B / B-2/B-3/C22/C-4/S/ C276/C-2000/G-35/G-30/X/N;Inconel: Inconel 100/600/601/602CA/617/625713/718738/X-750,Carpenter 20;Incoloy: Incoloy 800/800H/800HT/825/925/926;Monel: Monel 400/K500Nimonic: Nimonic 75/80A/90 ;OuterDiameter (OD)Peeling Bar: 16~180mmCold Drawn Bar: 4.76~120mm (All sizes can be customized)

Contacter maintenant

Application:Widely used in petroleum,foodstuff,chemical industry,construction, electricProduct Parameter:Prdouct NameNickel Alloy BarGradeHastelloy: Hastelloy B / B-2/B-3/C22/C-4/S/ C276/C-2000/G-35/G-30/X/N;Inconel: Inconel 100/600/601/602CA/617/625713/718738/X-750,Carpenter 20;Incoloy: Incoloy 800/800H/800HT/825/925/926;Monel: Monel 400/K500Nimonic: Nimonic 75/80A/90 ;OuterDiameter (OD)Peeling Bar: 16~180mmCold Drawn Bar: 4.76~120mm (All sizes can be customized)Forged Bar: 180~400mmLengthCustomizedApplicationAuto, turbines, blades, powder and engines,etcFeatureHigh corrosion resistance, low

Contacter maintenant

Alloy 400 (UNS N04400) is a single-phase solid-solution nickel-copper alloy with excellent corrosion resistance to a wide range of media.Product Parameter:Prdouct NameNickel Alloy BarGradeHastelloy: Hastelloy B / B-2/B-3/C22/C-4/S/ C276/C-2000/G-35/G-30/X/N;Inconel: Inconel 100/600/601/602CA/617/625713/718738/X-750,Carpenter 20;Incoloy: Incoloy 800/800H/800HT/825/925/926;Monel: Monel 400/K500Nimonic: Nimonic 75/80A/90 ;OuterDiameter (OD)Peeling Bar: 16~180mmCold Drawn Bar: 4.76~120mm (All sizes can be customized)Forged Bar: 180~400mmLengthCustomizedApplicationAuto, turbines, blades, powder and

Contacter maintenant

Nickel Base Alloy Plate It should be noted that active metals cannot be used in fluorine-containing environment (for example, Hastelloy C2000, NICU alloy, etc. can be used in hydrofluoric acid environment).Nickel Base Alloy is Active metals ,it also have good corrosion resistance, and the typical representative is Ti; Zr; TA et al; The most typical one is Ti; Titanium material has a wide range of applications, mainly used in some corrosion environments that stainless steel can not adapt to.

Contacter maintenant

Alloy X-750 exhibits excellent oxidation resistance to combustion gases at ambient temperatures up to 1600°F(870°C).Product Parameter:Prdouct NameNickel Alloy BarGradeHastelloy: Hastelloy B / B-2/B-3/C22/C-4/S/ C276/C-2000/G-35/G-30/X/N;Inconel: Inconel 100/600/601/602CA/617/625713/718738/X-750,Carpenter 20;Incoloy: Incoloy 800/800H/800HT/825/925/926;Monel: Monel 400/K500Nimonic: Nimonic 75/80A/90 ;OuterDiameter (OD)Peeling Bar: 16~180mmCold Drawn Bar: 4.76~120mm (All sizes can be customized)Forged Bar: 180~400mmLengthCustomizedApplicationAuto, turbines, blades, powder and engines,etcFeatureHi

Contacter maintenant

Alloy 718 (UNS N07718) is a high-strength, nickel-based superalloy made for long-term use in temperatures ranging from cryogenic up to 1200°F.

Contacter maintenant

This nickel based alloy produced in the form of rounds, squares, hexagons, rectangles as well as Alloy 601 Uns N06601 Cold Finished Bar apart from cold- worked wire, have been covered in the ASTM B166 specification.

Contacter maintenant

The alloy is resistant to high temperature corrosion properties such as oxidation and carbonization. The alloy is *** resistant to corrosion in hot corrosion areas such as sulfide environments, especially oxidation and carbonization up to 1100°C cycles. These corrosion resistance coupled with excellent mechanical properties make this alloy particularly suitable for high temperature applications.

Contacter maintenant

ApplicationWidely used in petroleum,foodstuff,chemical industry,construction, electricProduct Parameter:Prdouct NameNickel Alloy BarGradeHastelloy: Hastelloy B / B-2/B-3/C22/C-4/S/ C276/C-2000/G-35/G-30/X/N;Inconel: Inconel 100/600/601/602CA/617/625713/718738/X-750,Carpenter 20;Incoloy: Incoloy 800/800H/800HT/825/925/926;Monel: Monel 400/K500Nimonic: Nimonic 75/80A/90 ;OuterDiameter (OD)Peeling Bar: 16~180mmCold Drawn Bar: 4.76~120mm (All sizes can be customized)Forged Bar: 180~400mmLengthCustomizedApplicationAuto, turbines, blades, powder and engines,etcFeatureHigh corrosion resistance, low d

Contacter maintenant

Inconel 825 Nickel Base Alloy BarThe excessive nickel content material of Incoloy 825 offers the alloy an fantastic resistance to stress corrosion cracking. The corrosion resistance is gorgeous in a range of media, such as sulfuric, phosphoric, nitric and natural acids, alkali metals such as sodium hydroxide, potassium hydroxide and hydrochloric acid solutions.

Contacter maintenant

Product SpecificationThickness/Diameter>4 inchSingle Piece Length3 meter, 6 meterMaterialStainless SteelShapeRoundDiameter6 to 400 mmLength1 ~ 8 metersProduct DescriptionWe stock Bar, Hexagon, Square, Round products in various dimensions and grades. We stock Stainless steels supplied in the as rolled, annealed and normalized conditions.

Contacter maintenant

Inconel 825 Nickel Base Alloy Bar high nickel content ensures resistance to stress corrosion cracking, combined with molybdenum and copper to strongly resist reducing environments such as sulphuric and phosphoric acids, chromium to resist oxidising environments such as nitric acid, titanium to inhibit intergranular corrosion, and overall resistance to pitting and crevice corrosion.Product Parameter:Prdouct NameNickel Alloy BarGradeHastelloy: Hastelloy B / B-2/B-3/C22/C-4/S/ C276/C-2000/G-35/G-30/X/N;Inconel: Inconel 100/600/601/602CA/617/625713/718738/X-750,Carpenter 20;Incoloy: Incoloy 8

Contacter maintenant

600 alloy (UNS NO6600) The alloy is widely used in the chemical industry for its strength and corrosion resistance. Applications include heaters, stills, bubbles and condensers for fatty acid processing; Evaporator tubes, segments and spalling pans for the manufacture of sodium sulfide; And equipment for processing plants.

Contacter maintenant

Nickel Base Alloy C276 are tremendous for warmth exchangers inside the chemical processing and nuclear industries. they’re used in steam generator tubing inside the nuclear energy industry, in excessive-temperature aircraft structures, and in oil and fuel extraction packages in which corrosion-, stress- and temperature-resistant tubing is needed.

Contacter maintenant