904L Stainless Steel BarNickel base corrosion resistant alloys have austenite structure. In the state of solid solution and aging treatment, there are intermetallic phases and metal carbonitrides on the austenite matrix and grain boundary of the alloy.Ni Mo alloy is mainly used under the condition of reducing medium corrosion.

Contacter maintenant

C276 Nickel Base Alloy Bar Hastelloy C-276 CharacterThe key elements influencing corrosion resistance of this fabric are the control of impurity S,P, gascontent O,N and key factors C,Si, and so forth.It depends on the manage of manufacturing procedure, which include thepreference of heating temperature and heat maintenance time of forging, such as the assure of forgingratio, inclusive of the assure of strong answer remedy, and so on.Product Parameter:2.Chemical compositionCSMnPSNiCrMoFeCoWVMin14.515.04.03.0Max0.010.081.00.040.03Mar

Contacter maintenant

It has good corrosion resistance in low and medium temperature hydrochloric acid.

Contacter maintenant

UNS S32760 is able to compete strongly with the 6% molybdenum “super austenitic” grades in some applications, as it has fewer amounts of Mo and Ni which drive up the base cost of the material. Although, 32760 has lower amounts when compared to “6% Moly” grades it still has higher contents of Cr, Ni, and Mo when referring to other alloys, these elements improve the intergranular and pitting corrosion resistance of the material.

Contacter maintenant

Inconel 825 Nickel Base Alloy Bar high nickel content ensures resistance to stress corrosion cracking, combined with molybdenum and copper to strongly resist reducing environments such as sulphuric and phosphoric acids, chromium to resist oxidising environments such as nitric acid, titanium to inhibit intergranular corrosion, and overall resistance to pitting and crevice corrosion.Product Parameter:Prdouct NameNickel Alloy BarGradeHastelloy: Hastelloy B / B-2/B-3/C22/C-4/S/ C276/C-2000/G-35/G-30/X/N;Inconel: Inconel 100/600/601/602CA/617/625713/718738/X-750,Carpenter 20;Incoloy: Incoloy 8

Contacter maintenant

Bars are the most common raw material used by industries in various shapes and sizes, one such shape of the bar is Alloy 926 Round Bar. The most common shapes of Bars are Alloy 926 Round Bar, Alloy 926 Square Bar, Alloy 926 Rectangle Bar, and Alloy 926 Hex Bar.

Contacter maintenant

Chemical composition of Incoloy926 nickel base alloyThe content of Cr in nickel-based alloys is usually 14.0-18.0% and the content of nickel is 24.0-26.0%.

Contacter maintenant

Stainless steel bar has large utility possibilities, is widely utilized in hardware kitchenware, shipbuilding, petrochemical, equipment, medication, food, electric energy, power, building decoration, nuclear strength, aerospace, army industry and other industries! .

Contacter maintenant

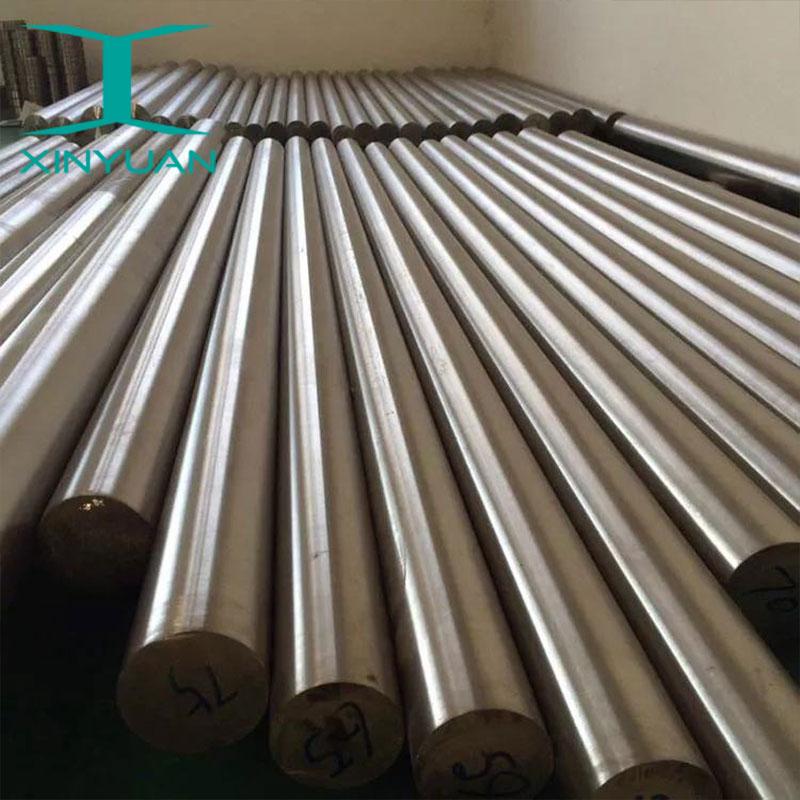

ApplicationWidely used in petroleum,foodstuff,chemical industry,construction, electricProduct Parameter:Prdouct NameNickel Alloy BarGradeHastelloy: Hastelloy B / B-2/B-3/C22/C-4/S/ C276/C-2000/G-35/G-30/X/N;Inconel: Inconel 100/600/601/602CA/617/625713/718738/X-750,Carpenter 20;Incoloy: Incoloy 800/800H/800HT/825/925/926;Monel: Monel 400/K500Nimonic: Nimonic 75/80A/90 ;OuterDiameter (OD)Peeling Bar: 16~180mmCold Drawn Bar: 4.76~120mm (All sizes can be customized)Forged Bar: 180~400mmLengthCustomizedApplicationAuto, turbines, blades, powder and engines,etcFeatureHigh corrosion resistance, low d

Contacter maintenant

Application:Widely used in petroleum,foodstuff,chemical industry,construction, electricProduct Parameter:Prdouct NameNickel Alloy BarGradeHastelloy: Hastelloy B / B-2/B-3/C22/C-4/S/ C276/C-2000/G-35/G-30/X/N;Inconel: Inconel 100/600/601/602CA/617/625713/718738/X-750,Carpenter 20;Incoloy: Incoloy 800/800H/800HT/825/925/926;Monel: Monel 400/K500Nimonic: Nimonic 75/80A/90 ;OuterDiameter (OD)Peeling Bar: 16~180mmCold Drawn Bar: 4.76~120mm (All sizes can be customized)Forged Bar: 180~400mmLengthCustomizedApplicationAuto, turbines, blades, powder and engines,etcFeatureHigh corrosion resistance, low

Contacter maintenant

HASTELLOY C-2000 The most versatile performanceCorrosion-resistant alloy with excellent uniform corrosion resistance in both oxidizing and reducing environments.Product Parameter:Prdouct NameNickel Alloy BarGradeHastelloy: Hastelloy B / B-2/B-3/C22/C-4/S/ C276/C-2000/G-35/G-30/X/N;Inconel: Inconel 100/600/601/602CA/617/625713/718738/X-750,Carpenter 20;Incoloy: Incoloy 800/800H/800HT/825/925/926;Monel: Monel 400/K500Nimonic: Nimonic 75/80A/90 ;OuterDiameter (OD)Peeling Bar: 16~180mmCold Drawn Bar: 4.76~120mm (All sizes can be customized)Forged Bar: 180~400mmLengthCustomizedApplicationAuto, turb

Contacter maintenant

Nickel Base Alloy Plate It should be noted that active metals cannot be used in fluorine-containing environment (for example, Hastelloy C2000, NICU alloy, etc. can be used in hydrofluoric acid environment).Nickel Base Alloy is Active metals ,it also have good corrosion resistance, and the typical representative is Ti; Zr; TA et al; The most typical one is Ti; Titanium material has a wide range of applications, mainly used in some corrosion environments that stainless steel can not adapt to.

Contacter maintenant

Alloy 625 (UNS NO6625) is used in combustion system transition bushings, propeller blades, seals, fasteners, pumps, turbine rings, heat exchanger tubes, reaction vessels, distillation towers, heat exchangers and valves.Product Parameter:Prdouct NameNickel Alloy BarGradeHastelloy: Hastelloy B / B-2/B-3/C22/C-4/S/ C276/C-2000/G-35/G-30/X/N;Inconel: Inconel 100/600/601/602CA/617/625713/718738/X-750,Carpenter 20;Incoloy: Incoloy 800/800H/800HT/825/925/926;Monel: Monel 400/K500Nimonic: Nimonic 75/80A/90 ;OuterDiameter (OD)Peeling Bar: 16~180mmCold Drawn Bar: 4.76~120mm (All sizes can be customized)

Contacter maintenant

Incoloy 330 is a nickel-ferrichrome austenite alloy.specifically designed for antioxidant and carburizing effects in high-temperature environments.Product Parameter:Prdouct NameNickel Alloy BarGradeHastelloy: Hastelloy B / B-2/B-3/C22/C-4/S/ C276/C-2000/G-35/G-30/X/N;Inconel: Inconel 100/600/601/602CA/617/625713/718738/X-750,Carpenter 20;Incoloy: Incoloy 800/800H/800HT/825/925/926;Monel: Monel 400/K500Nimonic: Nimonic 75/80A/90 ;OuterDiameter (OD)Peeling Bar: 16~180mmCold Drawn Bar: 4.76~120mm (All sizes can be customized)Forged Bar: 180~400mmLengthCustomizedApplicationAuto, turbines

Contacter maintenant

Inconel 825 Nickel Base Alloy BarThe excessive nickel content material of Incoloy 825 offers the alloy an fantastic resistance to stress corrosion cracking. The corrosion resistance is gorgeous in a range of media, such as sulfuric, phosphoric, nitric and natural acids, alkali metals such as sodium hydroxide, potassium hydroxide and hydrochloric acid solutions.

Contacter maintenant

Metallographic structure of Hastelloy B-3 Hastelloy B-3 has a face-centered cubic lattice structure.

Contacter maintenant

This nickel based alloy produced in the form of rounds, squares, hexagons, rectangles as well as Alloy 601 Uns N06601 Cold Finished Bar apart from cold- worked wire, have been covered in the ASTM B166 specification.

Contacter maintenant

Nickel Base Alloy C276 are tremendous for warmth exchangers inside the chemical processing and nuclear industries. they’re used in steam generator tubing inside the nuclear energy industry, in excessive-temperature aircraft structures, and in oil and fuel extraction packages in which corrosion-, stress- and temperature-resistant tubing is needed.

Contacter maintenant

Alloys Incoloy 800H and Incoloy 800HT are iron-nickel-chromium solid solution strengthened alloys with a nominal chemical composition of 42% iron, 34% nickel, and 22% chromium. These two grades are variations of the base grade 800 and are referred to by the tradenames Incoloy 800H and Incoloy 800HT and the universal designation UNS N08810 and N08811, respectively.

Contacter maintenant

Alloy 400 (UNS N04400) is a single-phase solid-solution nickel-copper alloy with excellent corrosion resistance to a wide range of media.Product Parameter:Prdouct NameNickel Alloy BarGradeHastelloy: Hastelloy B / B-2/B-3/C22/C-4/S/ C276/C-2000/G-35/G-30/X/N;Inconel: Inconel 100/600/601/602CA/617/625713/718738/X-750,Carpenter 20;Incoloy: Incoloy 800/800H/800HT/825/925/926;Monel: Monel 400/K500Nimonic: Nimonic 75/80A/90 ;OuterDiameter (OD)Peeling Bar: 16~180mmCold Drawn Bar: 4.76~120mm (All sizes can be customized)Forged Bar: 180~400mmLengthCustomizedApplicationAuto, turbines, blades, powder and

Contacter maintenant

Application is very wide, below 980 ℃ has sufficient strength and corrosion resistance and oxidation resistance.1.Manufacture of springs and bolts working under high temperature; rotor blades, impellers and other structural parts of gas turbines;2. Thrust chamber on rocket engines;3. Thrust reversal device on aircraft;4.

Contacter maintenant

Hastelloy B-2 Bar Hastelloy B-2 application fieldDue to the excellent corrosion resistance of Hastelloy B-2 bars● It is widely used in chemical, petrochemical, energy manufacturing and pollution control fields, especially in sulfuric acid, hydrochloric acid, phosphoric acid, acetic acid and other industries.

Contacter maintenant

317L hexagonal bar can be cold-drawn. For some demanding applications, 4% or more molybdenum in the welding coating of type 317 alloy hex bar is desirable.

Contacter maintenant

Inconel 625 Nickel Base Alloy PipeInconel 625 demonstrates an extraordinary mixture of corrosion resistance and excessive strength. Due to the excessive nickel content, alloy 625 is immune to chloride-induced stress corrosion cracking. It additionally has appropriate resistance to pitting and crevice corrosion.

Contacter maintenant