We produce and distribute warm rolled and laser fused chrome steel angles throughout the arena in each imperial and metric sizes. Please pick out the catalog on your area beneath to view a list of available standard size angles.

Contacter maintenant

We produce and distribute warm rolled and laser fused chrome steel angles for the duration of the arena in each imperial and metric sizes. Please select out the catalog in your location underneath to view a listing of to be had standard length angles.

Contacter maintenant

Stainless Steel Angles Slotted Angle Bar Perforated is a product which has legs to shape a ninety diploma perspective.This product is designed for use in both structural programs and fashionable fabrication.Stainless steel mind-set’s type of packages are vast and might consist of trailer production, protection cages, walkways and farming machine.

Contacter maintenant

310 Stainless Steel Angles are manufactured using high-grade steel, which contains chromium, nickel, and additional molybdenum, niobium, titanium, and nitrogen. These additional elements offer excellent tensile strength, high surface finish, outstanding corrosion & oxidation resistance, and good mechanical properties.

Contacter maintenant

We produce and distribute hot rolled and laser fused stainless steel angles during the arena in both imperial and metric sizes. Please pick out the catalog on your location underneath to view a listing of available fashionable size angles. We are a profile solutions enterprise, and custom shapes, sizes and alloys are to be had upon request.If you do now not see what you are looking for, please touch us, and our experienced body of workers will help guide you along with your custom profile needs.Products DescriptionProduct namestainless steel H-beam / I-beamStandardJIS, AiSi, ASTM, GB

Contacter maintenant

We produce and distribute hot rolled and laser fused stainless steel angles at some point of the area in each imperial and metric sizes. Please pick out the catalog on your location under to view a listing of to be had elegant size angles. We're a profile answers employer, and custom shapes, sizes and alloys are to be had upon request.In case you do now not see what you are searching out, please touch us, and our skilled frame of workers will help guide you along side your custom profile needs.Products DescriptionProduct namestainless steel H-beam / I-beamStandardJIS, AiSi, ASTM,

Contacter maintenant

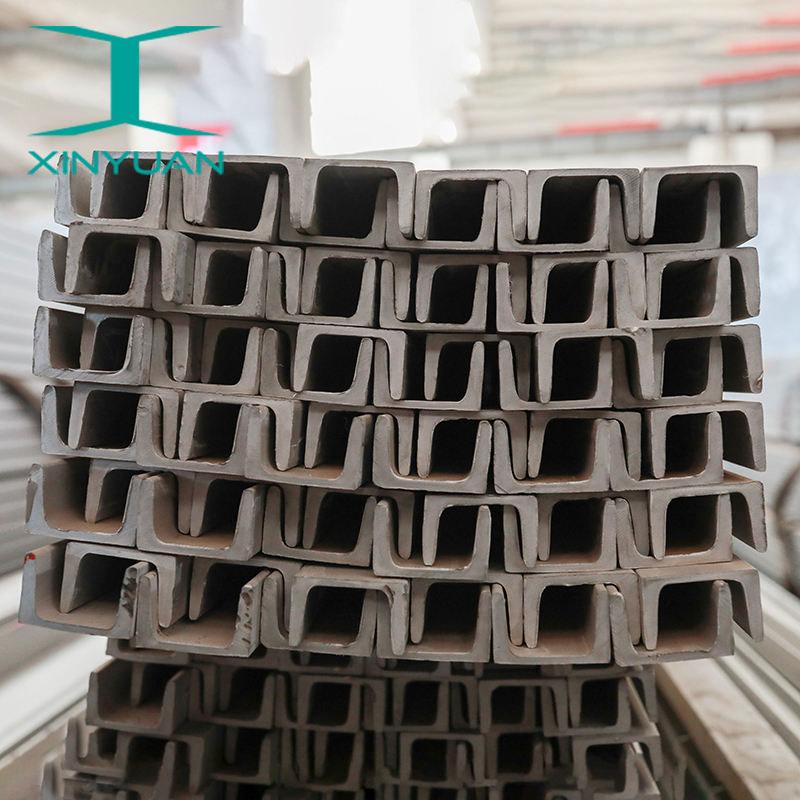

Our Stainless Steel 309 Angles/ Channels also has various advantages such as it has the heating elements, carbon saggers, waste incinerators, heat exchangers and much more.Product Parameter:Product NameStainless Steel ChannelSize50*37*4.5 - 400*104*14.5SurfaceBA, 2B, 2D, 4K, 6K, 8K, NO.4, HL, SB, EmbossedThinckness4.5mm-14.5mmWidthness50mm~2000mm or customizedLength1000mm~6000mm or customizedPackingIndustry standard packaging or according to client's requirementTechniqueCold Drawn/Cold pilfered/Cold rolled/Hot rolled/forge-Can be processed again repeatedlyStantardAISI, ASTM, BS, DIN, GB, J

Contacter maintenant

The 316 material can resist the chloride ion stress corrosion because of the 4% molybdenum in the content. There are different Stainless Steel 304 Unequal Angle Sizes depending on the application requirements. The angles are used to connect components together with a grip. There are angles with bolt holes for bolts or screws as well. The 316 Stainless Steel Unequal Angle is used in more corrosive applications than the 304 angles could be used. The Stainless Steel Unequal Angle is as common as the equal angle.

Contacter maintenant

The inner and outer flanges of H-beams are parallel or nearly parallel, and the ends of the flanges are at right angles, hence the name parallel flanged I-beams.

Contacter maintenant

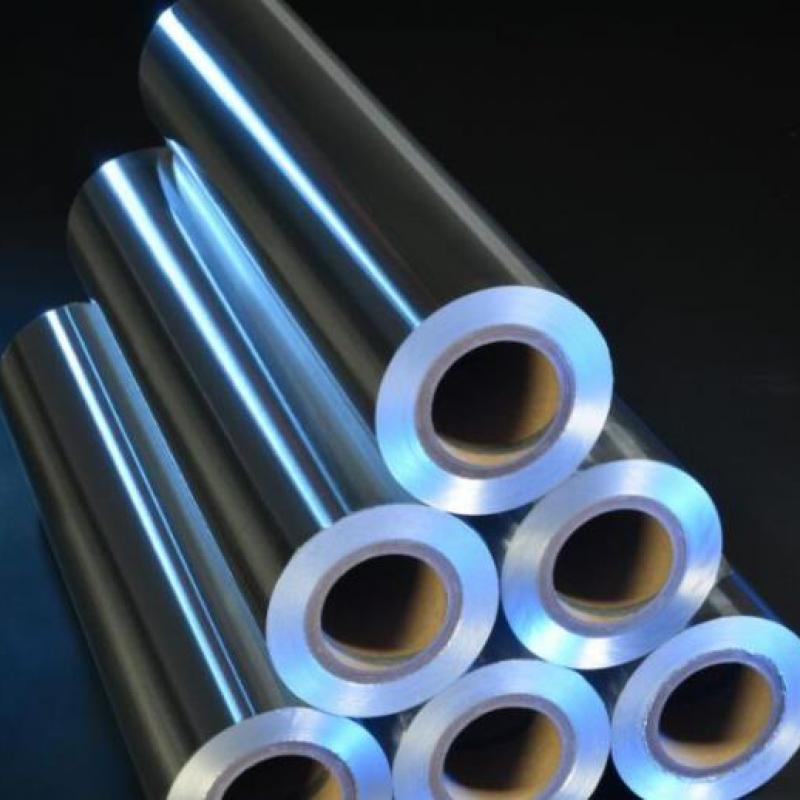

Through integrated production control, stainless steel foil that is excellent in etching properties and press formability, in addition to ultimately high thickness accuracy, strength, and spring characteristics. Stainless Steel FoilStainless steel foil is produced through the highly accurate rolling of stainless steel to be as thin as 100 mm, thus it has excellent flexibility, lightweight characteristics, and corrosion resistance.

Contacter maintenant

Mainly divided into equilateral stainless steel angle and unequal stainless steel angle two categories, which can be divided into unequal stainless steel angles and unequal thick and unequal unequal thick two.Product Parameter:NameStainless Steel angle barStandardASTM A276, A484, A479, A580, A582, JIS G4303, JIS G4311,DIN 1654- 5, DIN17440,GB/T 1220 ectMaterialMainly 201, 202, 304, 304L, 304H, 316, 316L,316Ti,2205, 330, 630, 660, 409L, 321, 310S, 410, 416, 410S, 430, 347H, 2Cr13, 3Cr13 et200series:201,202,202cu,204300series:301,302,303,304,304L,309,309s,310,310S,316,316L,316Ti, 317L,321,347400

Contacter maintenant

Laser fused stainless steel angles are made from two laser cut plates and run them through our 2 laser welded wires to create an overall uniform Angle iron with a strength mass equal to or exceeding that of a typical hot rolled and or extruded material.Product Parameter:NameStainless Steel angle barStandardASTM A276, A484, A479, A580, A582, JIS G4303, JIS G4311,DIN 1654- 5, DIN17440,GB/T 1220 ectMaterialMainly 201, 202, 304, 304L, 304H, 316, 316L,316Ti,2205, 330, 630, 660, 409L, 321, 310S, 410, 416, 410S, 430, 347H, 2Cr13, 3Cr13 et200series:201,202,202cu,204300series:301,302,303,304,304L,309,3

Contacter maintenant

According to the main chemical composition is divided into chromium stainless steel, chromium nickel stainless steel and chromium manganese nitrogen stainless steel; Can also be divided into acid resistant stainless steel and heat resistant stainless steel with performance characteristics; It is usually classified by metallographic structure.

Contacter maintenant

Type Stainless Steel SheetThicknessASIS,ASTM,DIN,JIS,JB,SUS,EN,etc.Size1000*2000mm, 1219*2438mm, 1219*3048mm or customized Max.

Contacter maintenant

630 stainless steel is martensitic precipitation hardening stainless steel.

Contacter maintenant

202 stainless steel is one of the 200 series stainless steel.

Contacter maintenant

304 is a universal stainless steel, which is widely used in the manufacture of equipment and parts requiring good comprehensive properties (corrosion resistance and formability). To maintain the corrosion resistance inherent in stainless steel, the steel must contain at least 18% chromium and at least 8% nickel.

Contacter maintenant

Most people have something made of stainless steel in their homes, whether it’s a kitchen appliance, some hardware, or even a piece of décor. Almost everybody knows what stainless steel is and what it looks like. Something that surprises many people is finding out there are actually multiple kinds of stainless steel. Check out this guide to learn more about the different types of stainless steel. Austenitic Austenitic stainless steel is designed to be nonmagnetic. A great example of an everyday application for austenitic stainless steel is a stainless steel oven.

Contacter maintenant

AISI 309L Stainless Steel Wire309S stainless steel -- S30908 (American AISI, ASTM) 309S. Most of the steel mills produce 309S stainless steel, which has good corrosion resistance and high temperature resistance. Withstands high temperatures of 980°C. Mainly used in boiler, chemical and other industries.

Contacter maintenant

Our variety of wire made of stainless steel aren't best recognized for their range but also are regarded for their excellent quality, lengthy lifestyles and really reasonable fees.

Contacter maintenant

The application of stainless steel flux cored wire is mainly MAG welding, MAG welding has the following characteristics; 1) Compared with manual welding, welding speed can be improved 2-4 times, its welding efficiency is up to 90%(stainless steel electrode only 55%)2) to the current, voltage adaptation range, welding conditions are easy to set, easy to conduct semi-automatic and automatic welding. 3) Good slag removal, welding pass surface gloss. In addition, the splash is very small, the arc stability is good, X-ray qualified.A .DescriptionA.

Contacter maintenant

Type 301 is an austenitic chromium-nickel stainless steel that is available in the annealed and cold worked conditions. In the annealed condition, Type 301 offers the highest level of stretch formability of any stainless steel and in the heavily cold worked condition offers the highest strength level of any 300 series stainless steel. Type 301 is non-magnetic in the annealed condition but becomes magnetic as a result of cold working.Type 301 is corrosion resistant in many environments, but the corrosion properties are less than that of 304/304L stainless steel.

Contacter maintenant

Our variety of wire made of stainless steel aren't best recognized for their range but also are regarded for their excellent quality, lengthy lifestyles and really reasonable fees.

Contacter maintenant

introduction:Welded stainless steel pipe provides us a large diameter but low cost solution. Our welding process mainly is Plasma-Arc Welding(PAW), its biggest diameter could reach 3000mm. If other process is required, please state it in the requirement of stainless steel tubings.Stainless steel contains chromium which provides the properties of corrosion resistance at high temperatures. Stainless steel can withstand corrosive or chemical environments due to its smooth surface.

Contacter maintenant