Flat welding flanges are suitable for pipeline systems with relatively low pressure levels and no serious pressure fluctuations, vibrations and shocks.

Contacter maintenant

Solid core stainless steel welding wire can be inert gas welding (TIG, MIG welding). It can also be used for submerged arc welding. MIG welding of stainless steel can not only achieve high efficiency welding, but also easy to realize welding automation, widely used in surfacing and thin plate welding and other fields.

Contacter maintenant

Butt welding ring loose flangeThe purpose of using butt welding ring loose flange is to save materials. The flange plate is made of low-grade material, and the pipe part is made of the same material as the pipe, so as to save material.Butt weld ring loose flange:1. Cost saving. When the pipe material is special and expensive, the cost of welding flanges of the same material is high.2. It is inconvenient for welding or processing or requires high strength. Such as plastic pipes, glass steel pipes and the like.3. Easy to construct.

Contacter maintenant

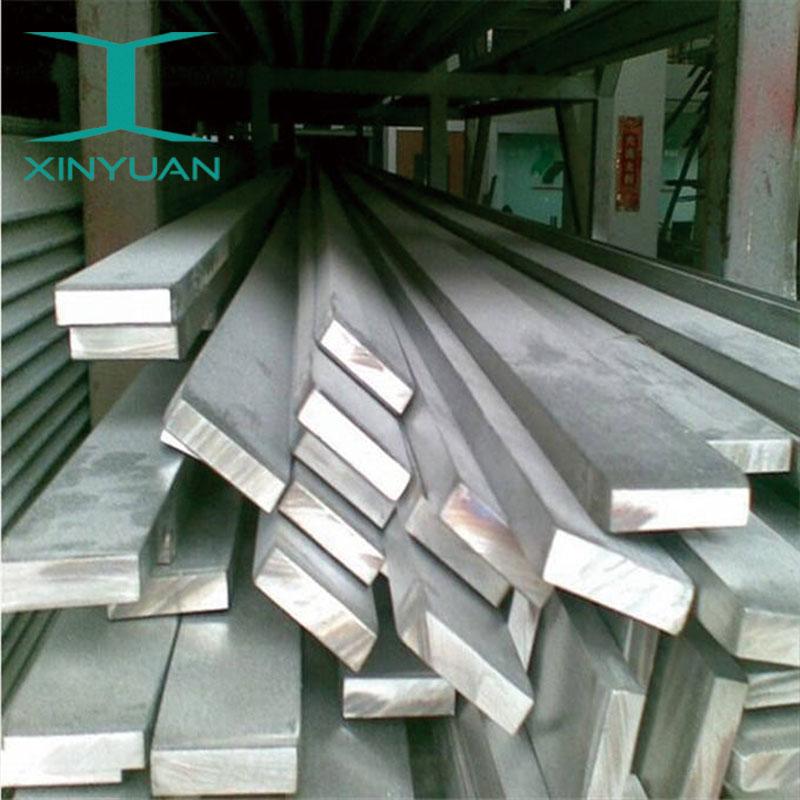

Material GradeSS 304ShapeFlatApplicationConstructionMaterialSSThickness3 mm to 200.00 mmWidth6 mm to 2000 mmMinimum Order Quantity50 kgProduct DescriptionWe are the pioneers in manufacturing and supplying the finest quality Stainless Steel Flat / Patta. This specially designed steel flat/patta is made using top quality stainless steel, which makes them durable and high in performance.

Contacter maintenant

Detailed content:Standard:AWS A 5.9YB/T5092Chemical Composition %CMnSiCrNiPSGradeER304≤0.081.0 – 2.5≤ 0.6017 – 198 – 11≤ 0.03≤ 0.03TypeSpool (MIG)Tube (TIG)Specification ( MM )0.8、0.9、1.0、1.2、1.6、2.01.6、2.0、2.4、3.2、4.0、5.0PackageS100/1kg S200/5kgS270,S300/15kg-20kg5kg/box 10kg/box length :1000MMMechanical PropertiesTensile Strength MpaElongation after fracture A(%)≥ 520≥ 30Diameter(MM)0.81.01.21.62.02.53.2Current(A)

Contacter maintenant

Our variety of wire made of stainless steel aren't best recognized for their range but also are regarded for their excellent quality, lengthy lifestyles and really reasonable fees.

Contacter maintenant

Products InfomationApplication:Used to weld ship building steel(A,B,D,E,A36,D36,E36)and equivalent mild steel or 550Mpa grade mild alloy steel, such as container building, construction machine, railway construction, pressure vessel for semi-auto or automatic gas shielded welding.It HAS excellent welding process performance, stable arc combustion, less spatter, beautiful weld forming, small stomatal sensitivity of weld metal, good all-position welding process, suitable for a wide welding current range.

Contacter maintenant

Stainless-steel flux cored cord may be like carbon metal and coffee alloy steel flux cored cord, chrome steel is simple and efficient welding, the application of chrome steel flux cored cord is specially magazine welding, mag welding has the following characteristics; 1) in comparison with manual welding, welding pace can be improved 2-4 instances, its welding performance is as much as ninety% (stainless-steel electrode only fifty five%) 2) to the cutting-edge, voltage adaptation variety, welding situations are smooth to set, smooth to conduct semi-computerized and automatic welding.

Contacter maintenant

The application of stainless steel flux cored wire is mainly MAG welding, MAG welding has the following characteristics; 1) Compared with manual welding, welding speed can be improved 2-4 times, its welding efficiency is up to 90%(stainless steel electrode only 55%)2) to the current, voltage adaptation range, welding conditions are easy to set, easy to conduct semi-automatic and automatic welding. 3) Good slag removal, welding pass surface gloss. In addition, the splash is very small, the arc stability is good, X-ray qualified.A .DescriptionA.

Contacter maintenant

DN25 DN40 DN80 DN100 DN150 DN600 SS304 316 WELDING NECK FLANGESItemDescriptionBasic InformationMaterial GradeWP304 , WP304L , WP304H , WP316 , WP316L , WP316Ti , WP309S , WP310S , WP321 , WP321H , WP347 , WP347H , F304 , F304L , F304H , F316 , F316L , F310S , F321 etcSize1/2" to 48" Sch 5S to XXSStandardASTM A403 etc .Process MethodForged / CastingIndustry & AdvantageApplicationa) Connect pipesAdvantagea) High technology ; good surface ; high quality etcTerms & ConditionsPrice ItemFOB , CFR , CIF or as negotiationPaymentT / T , LC or as negotiationDelivery Time 30 w

Contacter maintenant

416 Stainless Steel Flat Bar416 Stainless Steel Flat Bar is a free-machining version of martensitic stainless metal with the addition of sulphur or selenium that was once designed for multiplied machinability. 416 with the addition of sulfur makes it a free machining stainless steel. Heat therapy will harden 416 as nicely as amplify energy and hardness. This grade has higher machining. The fabric can be hardened by using warmth remedy to greater electricity and hardness levels.

Contacter maintenant

The 304L Stainless Steel Flat Bar is an austenitic metal that is made up of 18 percent chromium and 8 percent nickel. The carbon maximum for this grade of metal is 0.030 percent. This alloy is widely used because of its versatility. It is the most used stainless steel alloy in its family. 304L stainless steel is highly resistant to corrosion, even intergranular corrosion, which is caused by stress relieving or welding. Its low level of carbon makes it ideal for the majority of welded construction operations that use service temperatures that are limited to 800 degrees F.

Contacter maintenant

Class: E316HTX-XAWS: A5.22Conforms to Certification: AWS A5.22 ASME SFA A5.22Weld Process: Gas Metal ArcAWS Chemical Composition RequirementsC = 0.04 – 0.08S = 0.03 maxMn = 0.5 – 2.5Cr = 17.0 – 20.0Si = 1.0 maxNi = 11.0 – 14.0P = 0.04 maxMo = 2.0 – 3.0Cu = 0.75 maxApplicationElectrodes of this classification usually are used for welding similar alloys.

Contacter maintenant

410 stainless steel flat steel is widely used in decorative pipe, kitchenware, products with pipe. Food technology, sugar and wine making equipment. Beer piping. Cooling equipment. Water treatment equipment, electric transportation equipment, mechanical automation equipment, medical equipment, automobile accessories. Boiler auxiliary machine. Petrochemical, printing and dyeing equipment, heat exchanger, water supply and other industries.

Contacter maintenant

309S Stainless Steel Flux Cored Welding Wire309S Stainless Steel Flux Cored Welding Wire Compared with manual welding rod and argon arc welding wire, flux cored wire has obvious advantages, mainly changing the intermittent welding process into a continuous production mode, thus reducing the number of welding joints, improving the quality of welds, improving production efficiency and saving energy.309S Stainless Steel Flux Cored Welding Wire detailsProduct Parameter:CommodityStainless Steel Welded Wire/Stainless Steel RodSt

Contacter maintenant

ASTM A182 F304 304L F316 316L Stainless Steel Socket Welding FlangeItemDescriptionBasic InformationMaterial GradeWP304 , WP304L , WP304H , WP316 , WP316L , WP316Ti , WP309S , WP310S , WP321 , WP321H , WP347 , WP347H , F304 , F304L , F304H , F316 , F316L , F310S , F321 etcSize1/2" to 48" Sch 5S to XXSStandardASTM A403 etc .Process MethodForged / CastingIndustry & AdvantageApplicationa) Connect pipesAdvantagea) High technology ; good surface ; high quality etcTerms & ConditionsPrice ItemFOB , CFR , CIF or as negotiationPaymentT / T , LC or as negotiationDelivery Time

Contacter maintenant

The most widely used of the stainless and heat resisting steels, 304 offers good corrosion resistance to many chemical corrodents as well as industrial atmospheres.304 Stainless Steel Flat Bar has very good formability and can be readily welded by all common methods.

Contacter maintenant

ER316/316L is used for welding types 316 and 316L stainless steels. It has a maximum carbon content of .03% to reduce the possibility of formation of intergranular carbide precipitation. This low carbon alloy is not as strong as 316H at elevated temperatures.Typical Applications: primarily used for welding low carbon molybdenum bearing austenitic alloys AWS Class: ER316/316LCertification: AWS A5.9/A5.9M:2006Alloy: ER316/316LAWS/ASME SFA A5.9&nb

Contacter maintenant

Stainless Steel UNS S20200 Flat Bars has related mechanical properties as liken to 304 Stainless Steel, but its capability to fight corrosion is less to some extent as relate to AISI 304 grade in chloride atmosphere. In spite of lower toughness and less corrosion-resistant, it offers low-cost alternate to SS 304 in food processing and kitchenware field applications.

Contacter maintenant

ER410 H1Cr13 Y410 510 25 13Cr steel, the deposited metal is 13Cr, with high hardenability, excellent oxidation resistance and corrosion resistance at high temperature, suitable for welding of AISI410 or 420.ER410 flux-cored stainless steel wire Application: used for welding 410 or 420 series stainless steel, with high hardening, high temperature oxidation resistance, corrosion resistance, used in petroleum refining and chemical industry and surfacing repair, such as 12Cr13 (sus410)Products DescriptionWarranty3 yearsCustomized supportOEM, ODMPlace of OriginChinaBrand NameXINYUANModel NumberER41

Contacter maintenant

316 Stainless Steel Flat Bar: 316 Stainless is ideally suited for corrosion resistance against a wide range of chemical and acidic corrodents, and marine environment applications. Typical uses of 316 Stainless include food production, pharmaceutical equipment, furnace parts, heat exchangers, valves and pumps, chemical equipment, and parts for marine use.

Contacter maintenant

309S stainless steel flat steel characteristics: can withstand 980 repeated heating, with high temperature strength and oxidation resistance, carburizing resistanceProduct Parameter:ITEMStainless Steel Flats bar SizeWidth 3-500mm;Thickness0.3-120mm;Length:1000-600mm(or as your request)SurfaceBlack, pickled, bright, ground as per customers' requirementFinish Hot rolled, cold drawn, hot forgedMaterial201.202.301.302.304.304L.310S.316.316L.321.430.430A.309S.2205.2507.2520.430.410.440.904Lect.

Contacter maintenant

321 stainless steel flat bar, also known as UNS S32100 and Grade 321, is primarily comprised of 17% to 19% chromium, 12% nickel, .25% to 1% silicon, 2% maximum manganese, traces of phosphorus and sulfur, 5 x (c + n) .70% titanium, with the balance being iron. With regards to corrosion resistance, 321 is equivalent to Grade 304 in the annealed condition and is superior if the application involves service in the 797° to 1652° F range.

Contacter maintenant

Flat Welded Flange With Neck XINYUAN has been engaged in theStainless steel production and supply of various flanges and pipe fittings for more than 15 years. Our flagship products include pipes, flanges, elbows, elbows, tees, reducers, caps, forged fittings, bolts and nuts, washers, profiles and other fittings that meet all national and internationally recognized standards.

Contacter maintenant