Stainless-steel sample plate is embossed by way of mechanical gadget on the chrome steel plate, in order that the floor of the concave and convex pattern. Due to the splendid corrosion resistance and skid resistance of stainless steel sample plate has been used by many industries and started to be famous. The pattern sample of the earliest stainless-steel sample plate is horizontal and vertical stripes crisscrossed, inside the subsequent 20-30 years researchers through non-stop experiments and improvements to have a higher anti-skid sample design is now additionally big-scale produ

Contacter maintenant

Stainless-steel pattern plate is embossed thru way of mechanical gadget at the stainless-steel plate, in order that the floor of the concave and convex sample. Because of the splendid corrosion resistance and skid resistance of stainless steel sample plate has been used by many industries and started out to be well-known. The pattern sample of the earliest stainless-steel sample plate is horizontal and vertical stripes crisscrossed, within the subsequent 20-30 years researchers through non-stop experiments and improvements to have a better anti-skid pattern layout is now

Contacter maintenant

Products DescriptionStainless steel plate of its confined overall performance of the choice, the overall low precision seamless metallic pipe : wall thickness isn't uniform, stainless steel plate's floor brightness is low, stainless-steel plate's value of excessive-period, and the advent of pitting, black spots are not smooth to cast off.Product Namel stainless steel plateThickness0.1~150mmWidth600mm,1000mm,1219mm,1500mm,1800mm,2000mm,2500mm, 3000mm, 3500mm,etcLength2000mm, 2440mm, 3000mm, 5800mm, 6000mm, etcStandardASTM GB/T JIS4 ASME BS DIN ENMaterial200 series: 201/202300 series

Contacter maintenant

Products DescriptionStainless steel plate of its restrained ordinary performance of the choice, the general low precision seamless metal pipe : wall thickness is not uniform, stainless-steel plate's floor brightness is low, stainless-steel plate's cost of immoderate-length, and the arrival of pitting, black spots are not clean to get rid of. Product Namel stainless steel plateThickness0.1~150mmWidth600mm,1000mm,1219mm,1500mm,1800mm,2000mm,2500mm, 3000mm, 3500mm,etcLength2000mm, 2440mm, 3000mm, 5800mm, 6000mm, etcStandardASTM GB/T JIS4 ASME BS DIN ENMaterial200 series: 201/202300 s

Contacter maintenant

Stainless-steel coil/strip;stainless steel 430 ba coil; stainless steel cold rolled strip;stainless steel cold rolled coil;stainless steel coil 201/304/430 products description product call:bloodless rolled stainless-steel coils, cease 2b/ba, slight deep drawing first rate 1) grade: 201, 304, 410, 430 and so on. 2) floor finish: 2b, no.4, ba, 8k, etched/embossed and so on 3) coils width: 60mm---1250mm 4) thickness: 0.3.zero mm 5) packing: export package deal, wood batten or as consistent with patron's request 6) application: constructing substances, decoration

Contacter maintenant

Hot Rolled Stainless Steel CoilHot Rolled stainless steel coils are one of the most sought after types of raw material in the construction and manufacturing industries. Thanks to their distinct mechanical and physical properties, hot rolled stainless steel coils have been widely used in the production of kitchen appliances to industrial equipment. Hot rolled stainless steel coils are strong, resist corrosion, are light in weight and require low maintenance.

Contacter maintenant

321 stainless steel of Ti as a stabilizing element exists, but it is also a hot steel, in terms of high temperature is better than 316 l. 321 stainless steel in different concentration and temperature of organic acid and inorganic acid, especially in oxidizing medium has good abrasion resistance, used in the manufacture of the lining of wear resistant acid containers and equipment and pipelines.

Contacter maintenant

Ti in 321 stainless steel exists as a stabilizing element, but it is also a heat-strong steel, which is much better than 316L in the aspect of high temperature.321 stainless steel has good abrasion resistance in organic and inorganic acids at different concentrations and temperatures, especially in oxidizing media, and is used for the manufacture of wear-resistant acid containers and wear-resistant equipment lining, conveying pipeline.Product Parameter:StandardASTM A479,ASTM A276,ASTM A484, ASTM A582, ASME SA276, ASME SA484, GB/T1220, GB4226,&n

Contacter maintenant

A 310s stainless-steel bar is a sort of stainless steel alloy that carries high degrees of chromium, nickel, and a mild quantity of carbon. the "310s" designation refers back to the unique grade of stainless-steel and indicates that it contains 25-28% chromium and 19-22% nickel.310s chrome steel is known for its outstanding oxidation resistance at high temperatures and its potential to face up to thermal biking.

Contacter maintenant

317L Austenitic Stainless Steel Wire 317L Austenitic Stainless Steel Wire ’s Mechanical properties:317L mechanical properties: ys (MPA) ≥ 176, TS (MPA) ≥ 480, EL (%) ≥ 40, HV ≤ 200317L Austenitic Stainless Steel Wire 's chemical composition317L chemical composition: carbon (c) ≤ 0.030, manganese (MN) ≤ 2.00, nickel (Ni) 11.0 ~ 15.0, silicon (SI) ≤ 1.00, phosphorus (P) ≤ 0.045, sulfur (s) ≤ 0.030, chromium (CR) 18.0 ~ 20.0, molybdenum (MO) 3.0 ~ 4.0Product Parameter:Weight1000(kg/km)Diameter0.2-14mmLengthAs requirementsMaterial201,301,302,303,304,304L,316,316L,317L,321,308,308L,309,309

Contacter maintenant

The alloy is resistant to high temperature corrosion properties such as oxidation and carbonization. The alloy is *** resistant to corrosion in hot corrosion areas such as sulfide environments, especially oxidation and carbonization up to 1100°C cycles. These corrosion resistance coupled with excellent mechanical properties make this alloy particularly suitable for high temperature applications.

Contacter maintenant

It has good corrosion resistance in low and medium temperature hydrochloric acid.

Contacter maintenant

This austenite crystalline structure is achieved by sufficient additions of the austenite stabilizing elements nickel, manganese and nitrogen. Due to their crystalline structure, austenitic steels are not hardenable by heat treatment and are essentially non-magnetic.There are two subgroups of austenitic stainless steel. 300 series stainless steels achieve their austenitic structure primarily by a nickel addition while 200 series stainless steels substitute manganese and nitrogen for nickel, though there is still a small nickel content.300 series stainless steels are the larger subgroup.

Contacter maintenant

202 stainless steel is one of the 200 series stainless steels, the national standard model is 1Cr18Mn8Ni5N. The 200 series stainless steel belongs to low nickel and high manganese stainless steel with a nickel content of about 8% and a manganese content of about 8%.

Contacter maintenant

304L stainless steel is also known as environmentally friendly low-carbon stainless steel. As a low-carbon 304 stainless steel, its corrosion resistance is similar to that of 304 in general use scenarios, but 304L stainless steel can also maintain good resistance after welding or stress relief. It has excellent corrosion resistance and can maintain excellent corrosion resistance without heat treatment. The operating temperature range can reach -196℃-800℃.

Contacter maintenant

321 stainless steel is a Ni-Cr-Mo type austenitic stainless steel, its properties are very similar to 304, but due to the addition of metal titanium, it has better resistance to grain boundary corrosion and high temperature strength. Due to the addition of metallic titanium, it effectively controls the formation of chromium carbide. Ti in 21 stainless steel exists as a stabilizing element, but it is also a heat-strength steel, which is much better than 316L in high temperature.

Contacter maintenant

Good appearance and surface quality, suitable for all-weather construction, little affected by climate conditions.

Contacter maintenant

Inconel600 alloy has satisfactory thermal strength and high plasticity below 800C.

Contacter maintenant

2Cr13 stainless steel has high hardness and good corrosion resistance during quenching. Many of them are used for cutting tools. They are "cutting tool grade" martensitic steel.

Contacter maintenant

Stainless Steel Square Bar 316/316L is a square shaped 316/316L Stainless Steel Alloy bar.316 Stainless Steel Alloy is a standard molybdenum-bearing grade, the second most commonly sought after grade next to grade 304 amongst the austenitic stainless steels.Product Parameter:StandardASTM A479,ASTM A276,ASTM A484, ASTM A582, ASME SA276, ASME SA484, GB/T1220, GB4226, etc.Material301, 304, 304L, 309S, 321, 316, 316L, 317, 317L, 310S, 201,202321, 329, 347, 347H 201, 202, 410, 420, 430, S2

Contacter maintenant

310 Stainless Steel Angles are manufactured using high-grade steel, which contains chromium, nickel, and additional molybdenum, niobium, titanium, and nitrogen. These additional elements offer excellent tensile strength, high surface finish, outstanding corrosion & oxidation resistance, and good mechanical properties.

Contacter maintenant

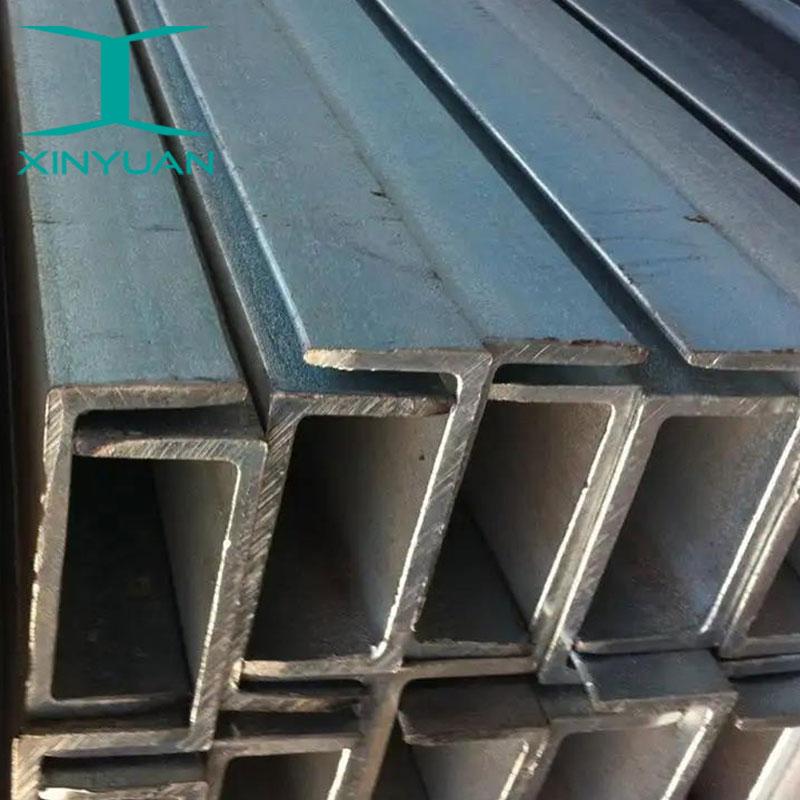

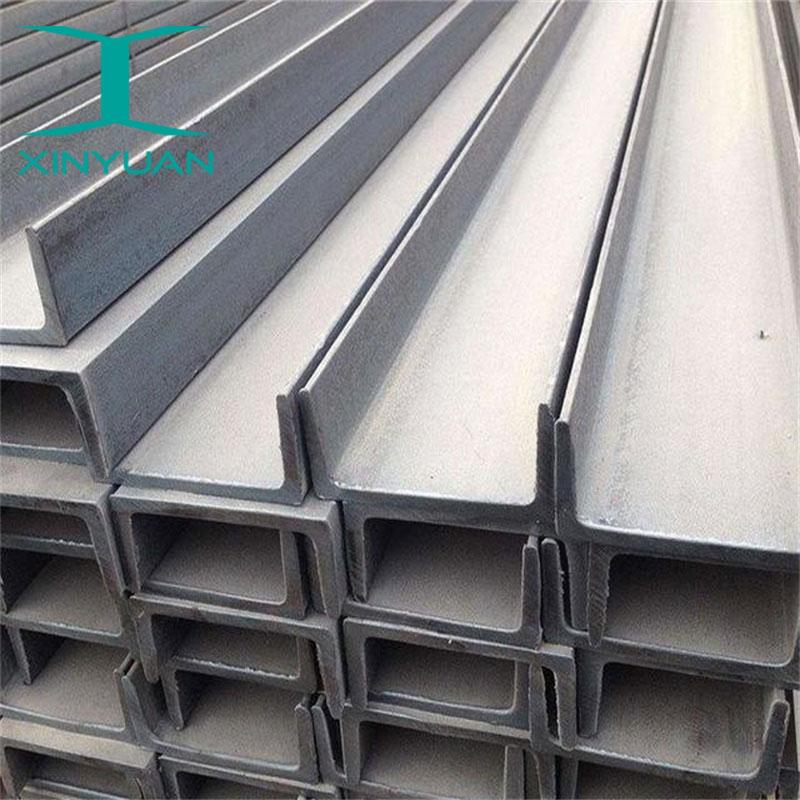

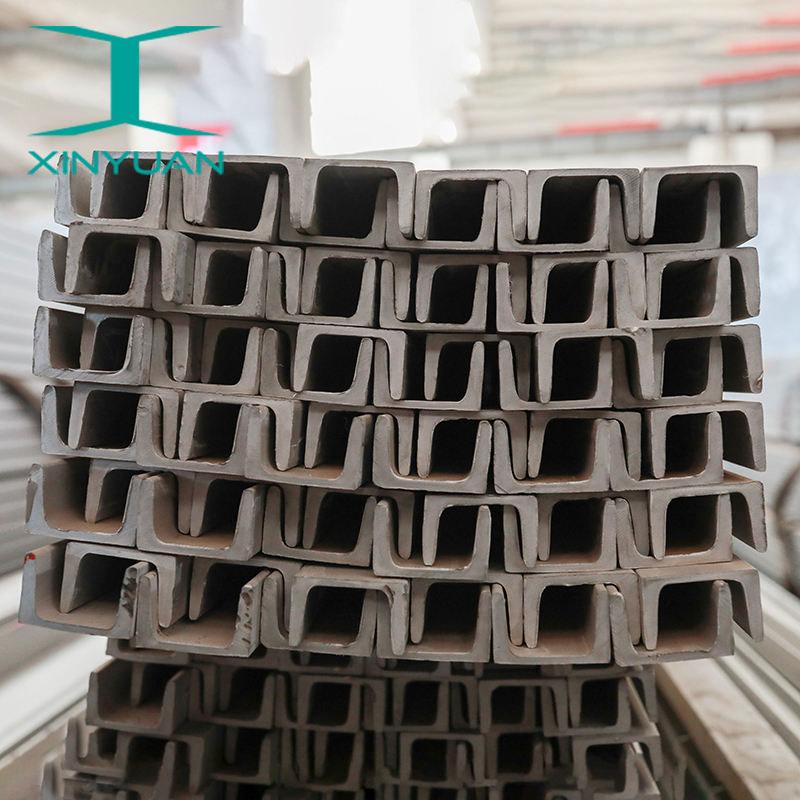

Our Stainless Steel 309 Angles/ Channels also has various advantages such as it has the heating elements, carbon saggers, waste incinerators, heat exchangers and much more.Product Parameter:Product NameStainless Steel ChannelSize50*37*4.5 - 400*104*14.5SurfaceBA, 2B, 2D, 4K, 6K, 8K, NO.4, HL, SB, EmbossedThinckness4.5mm-14.5mmWidthness50mm~2000mm or customizedLength1000mm~6000mm or customizedPackingIndustry standard packaging or according to client's requirementTechniqueCold Drawn/Cold pilfered/Cold rolled/Hot rolled/forge-Can be processed again repeatedlyStantardAISI, ASTM, BS, DIN, GB, J

Contacter maintenant

Application is very wide, below 980 ℃ has sufficient strength and corrosion resistance and oxidation resistance.1.Manufacture of springs and bolts working under high temperature; rotor blades, impellers and other structural parts of gas turbines;2. Thrust chamber on rocket engines;3. Thrust reversal device on aircraft;4.

Contacter maintenant

SL Food Grade 19mm/25/32/38/45/51mm OD Sanitary Butt Weld 90 Degree Elbow Bend Pipe 304 stainless steel FittingProduct Description of Stainless Steel ElbowPIPE FITTINGSProduction Name45 / 90 / 180 , Long / Short Radius Elbows, Equal / Reducing Crosses, Concentric / Eccentric Reducers, Caps, Stub EndsSize RangeFrom ½" up to 72" From 1/2 to 30 (Seamless Pipe Fittings),Form16to 72(Seam Pipe Fittings)Sched

Contacter maintenant