Stainless steel with 12%~30% chromium and ferritic matrix of body - centered cubic lattice at high temperature and room temperature. This kind of steel generally does not contain nickel, some contain a small amount of molybdenum, titanium or niobium and other elements, with good oxidation resistance, corrosion resistance and chloride corrosion cracking resistance.

Contacter maintenant

Brilliant chrome steel coil refers to a type of stainless-steel coil that has a elegant or reflective surface finish. this finish is done through a process called electropolishing or by using the use of abrasives in the course of the manufacturing process.The bright surface end on chrome steel coils gives several blessings. it provides a clean and appealing appearance, making it a popular choice for ornamental applications, including trim, architectural capabilities, and jewelry.

Contacter maintenant

Stainless-steel coil/strip;stainless steel 430 ba coil; stainless steel cold rolled strip;stainless-steel cold rolled coil;stainless steel coil 201/304/430 merchandise description product name:cold rolled stainless-steel coils, cease 2b/ba, mild deep drawing great 1) grade: 201, 304, 410, 430 etc.

Contacter maintenant

Stainless-steel coil/strip;stainless steel 430 ba coil; stainless-steel bloodless rolled strip;stainless steel cold rolled coil;stainless-steel coil 201/304/430 merchandise description product call:bloodless rolled stainless steel coils, cease 2b/ba, slight deep drawing extraordinary 1) grade: 201, 304, 410, 430 and so on. 2) ground end: 2b, no.four, ba, 8k, etched/embossed and so forth 3) coils width: 60mm---1250mm 4) thickness: zero.3.zero mm 5) packing: export bundle deal, timber batten or as regular with customer's request 6) software: building substances,

Contacter maintenant

Stainless steel coil/strip;chrome steel 430 ba coil; stainless-steel cold rolled strip;stainless-steel bloodless rolled coil;chrome steel coil 201/304/430 merchandise description product name:bloodless rolled stainless steel coils, end 2b/ba, gentle deep drawing excellent 1) grade: 201, 304, 316L 410, 430 etc. 2) surface finish: 2b, no.4, ba, 8k, etched/embossed etc 3) coils width: 60mm---1250mm four) thickness: zero.3.0 mm 5) packing: export bundle, wooden batten or as in step with customer's request 6) utility: constructing materials, decoration subject, domestic

Contacter maintenant

Stainless steel coil: Material: SUS201, 202, 304, 316L, 316Ti, 321, 304L, 441, 444, 436, 439, 430, 409L, 410S, 309S, 310S, 904L, 2205, 2507, etc. Thickness: 0.3-16.0mm, width 1 meter, 1.22 meters, 1.5 meters, 1.8 meters, 2 meters, non-standard can be customized. Stainless steel properties:As a widely used steel, has good corrosion resistance, heat resistance, low temperature strength and mechanical properties; Stamping, bending and other hot workability, no heat treatment hardening phenomenon (use temperature -196℃~800℃). Household products (cl

Contacter maintenant

Stainless steel coil is one of the most popular raw materials in construction and manufacturing. Because of its unique mechanical and physical properties, stainless steel coils have been widely used in the production of kitchen appliances and industrial equipment. They are rugged, corrosion resistant, lightweight and require low maintenance. In addition, they are flexible and easy to meet the requirements of a series of design standards. In industry (especially in manufacturing), many grades of stainless steel coils can be found, each with different performance and availability.

Contacter maintenant

430 Stainless Steel CoilBy some distance the most famous of all straight-chromium stainless steels, Type 430 is the general-purpose alloy of the ferritic class. Referred to as “17 Chrome stainless,” this grade presents favorable resistance to slight atmospheric corrosion and oxidizing environments. Its resistance to corrosion can be superior and reflectivity accelerated with vivid annealing.Type 430 is acknowledged to have reasonable ductility constrained forming, bending and welding traits and can be drawn to a reasonable degree.

Contacter maintenant

254SMO is an austenitic stainless steel. Because of its high molybdenum content, it has very high resistance to spot corrosion and crevice corrosion. Main ingredients:254 smo carbon (C) 0.02 or less, manganese (Mn) of 1.00 or less, nickel (Ni) 17.5 ~ 18.5, silicon (Si) of 0.8 or less phosphorus (P) of 0.03 or less, sulfur (S) of 0.01 or less, chromium (Cr) 19.5 ~ 20.5, copper (Cu) 0.5 ~ 1.0, molybdenum (Mo) 6.0 ~ 6.5 National standards: UNS S31254, DIN/EN 1.4547, ASTM A280, ASME SA-240 Welding material: ERNiCrMo-3 wire, ENiCrMo-3 electrode Product Name254smo st

Contacter maintenant

OverviewProductstainless steel coil StandardJIS, AISI, ASTM, GB, DIN, EN, etc.Material410 420 430 440C 201 202 301 304 304L 304H 316 316L 316Ti 321 310S 309S 904L 2205 2507 etc.Thickness0.3-3mm, or according to the customers' request.Width1000-2000mm, or according to the customers' request.Length2000-4000mm, or according to the customers' request.CertificateBV, ISO, SGS, etc.ApplicationConstruction/Indutry/BuildingMOQ1 TonBrandPuxinTypePlate / SheetPortAny ports of ChinaPaymentL/C, T/TSurface finishChemical Properties of Frequently-used Stainless Steel Material GradeUNSA

Contacter maintenant

Stainless-steel coil/strip;stainless steel 430 ba coil; stainless steel cold rolled strip;stainless steel cold rolled coil;stainless steel coil 201/304/430 products description product call:bloodless rolled stainless-steel coils, cease 2b/ba, slight deep drawing first rate 1) grade: 201, 304, 410, 430 and so on. 2) floor finish: 2b, no.4, ba, 8k, etched/embossed and so on 3) coils width: 60mm---1250mm 4) thickness: 0.3.zero mm 5) packing: export package deal, wood batten or as consistent with patron's request 6) application: constructing substances, decoration

Contacter maintenant

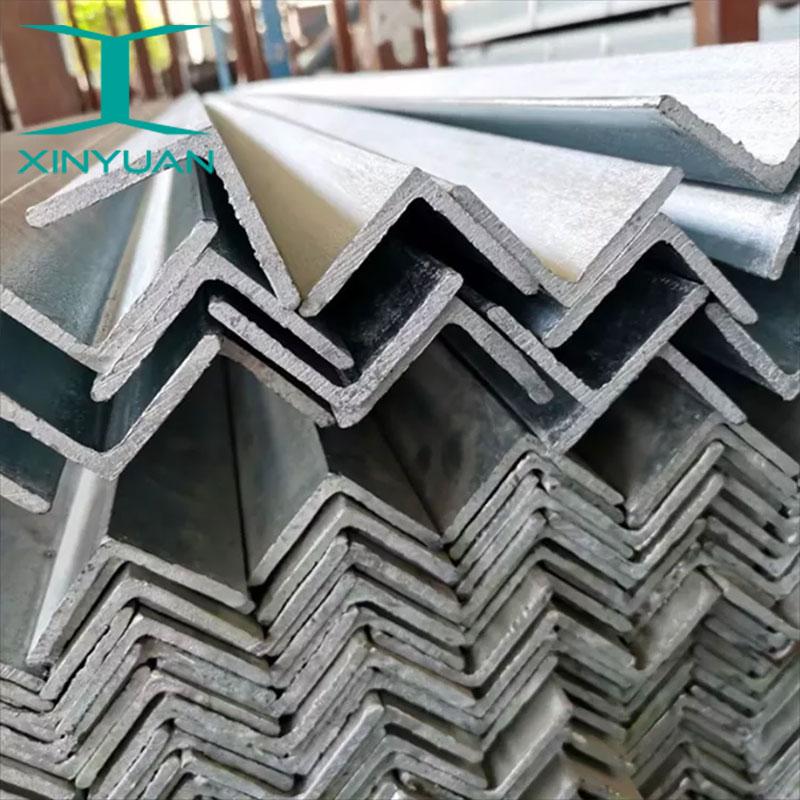

430 stainless steel is used for architectural decoration, fuel burner parts, household appliances, and home appliance parts. 430 is a ferritic stainless steel, and 430 16Cr is a representative steel grade of ferritic steel, with good thermal expansion rate, excellent formability and oxidation resistance.

Contacter maintenant

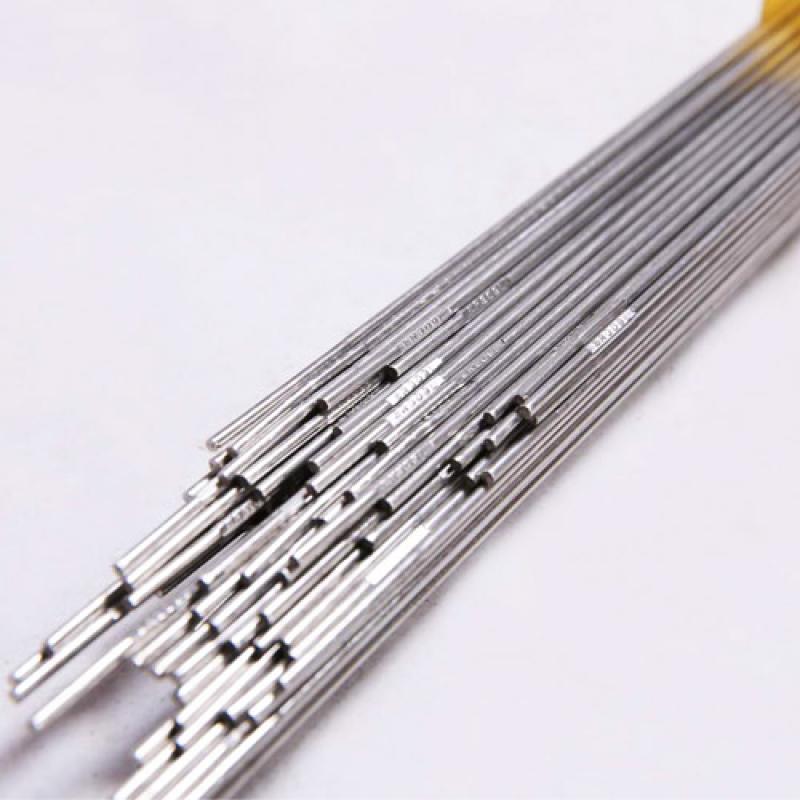

Available SizesDiameter X Spool SizesDiameter X Coil Sizes.025 x 2#, 10#, 25#1/16 x 60# & mill coil.030 x 2#, 10#, 25#, 30#, 33#5/64 x 60# & mill coil.035 x 2#, 10#, 25#, 30#, 33#3/32 x 60# & mill coil.045 x 2#, 10#, 25#, 30#, 33#1/8 x 60# & mill coil1/16 x 10#, 25#, 30#, 33#3/16 x 60# & mill coil5/32 x 60# & mill coilApplicationWW308 is used to MIG, and submerged arc welding of un-stabilized stainless steels such as Types 301, 302, 304, 305, 308.

Contacter maintenant

Provide stainless steel coil 304 / 316 / 316L /310 / 321 / 904 etc, fast delivery, order! High quality stainless steel manufacturer, competitive price, good service, contact now! Short Leading Time。Manufacturer & Supplier。Rich Stock, Fast Delivery。

Contacter maintenant

PROFILE201 stainless steel has a certain acid resistance, alkali resistance, high density, polishing no bubble, no pinhole and other characteristics, is the production of all kinds of watch case, watchband bottom cover quality materials. Mainly used for decorative pipe, industrial pipe, some shallow stretching products.201 Stainless steel coil price is lower compared to other grades of stainless steels and all metallic products in general.

Contacter maintenant

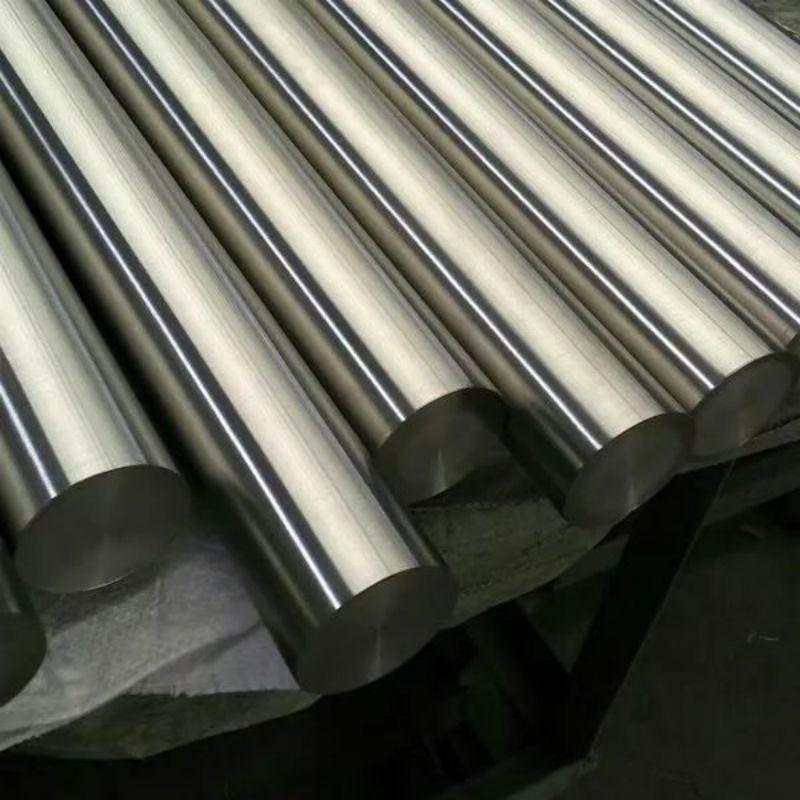

430 stainless steel is a type of ferritic stainless-steel that consists of chromium, which gives it its corrosion-resistant properties. the primary alloying element in 430 stainless-steel is chromium, generally starting from 16 to 18 percentage. it additionally has a low carbon content material, which improves its weldability.430 stainless-steel bars are generally utilized in various packages due to their desirable mixture of corrosion resistance, formability, and affordability.

Contacter maintenant

Stainless steel coil is one of the most popular raw materials in construction and manufacturing. Because of its unique mechanical and physical properties, stainless steel coils have been widely used in the production of kitchen appliances and industrial equipment. They are rugged, corrosion resistant, lightweight and require low maintenance. In addition, they are flexible and easy to meet the requirements of a series of design standards. In industry (especially in manufacturing), many grades of stainless steel coils can be found, each with different performance and availability.

Contacter maintenant

ER308,ER308L,ER308Si,ER308LSi,ER309,ER309L,ER310,ER316,ER316L;AWS: A5.9Conforms to Certification: AWS A5.9 ASME SFA A5.9Weld Process Used for Mig (GMAW) and Submerged Arc (SAW)AWS Chemical CompositionC = 0.08 maxCr = 19.5 – 22.0Ni = 9.0 – 11.0Mo = 0.75 maxMn = 1.0 – 2.5Si = 0.30 – 0.65P = 0.03 maxS = 0.03 maxCu = 0.75 maxAvailable SizesDiameter X Spool SizesDiameter X Coil Sizes.025 x 2#, 10#, 25#1/16 x 60# & mill coil.030 x 2#, 10#, 25#, 30#, 33#5/64 x 60# & mill coil.035 x 2#, 10#, 25#, 30#, 33#3/32 x 60# & mill coil.045 x 2#, 10#, 25#, 30#, 33#1/8 x 60# & mi

Contacter maintenant

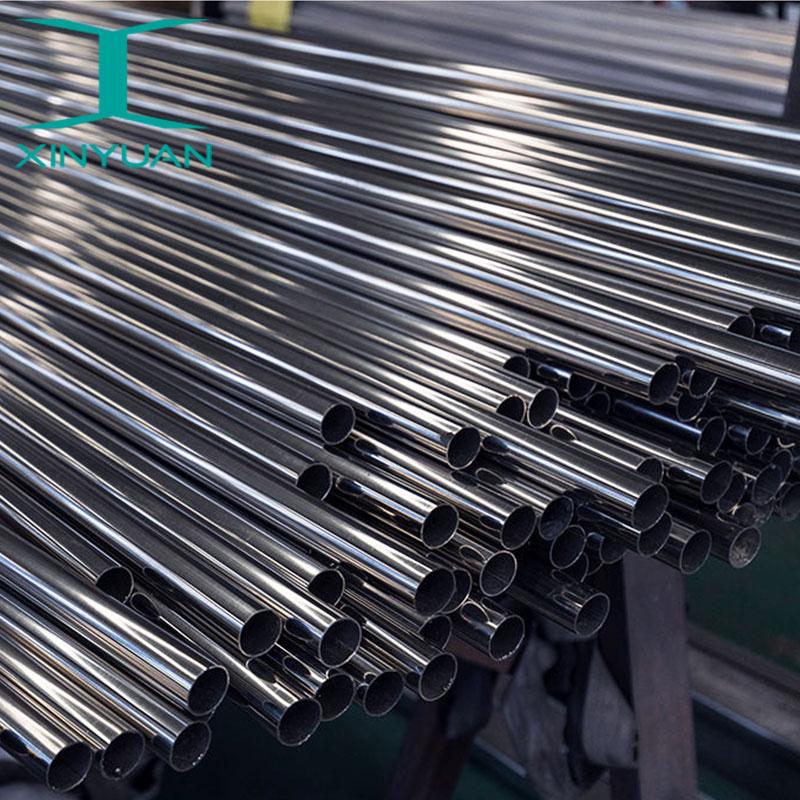

Products DescriptionStainless steel is notable for its corrosion resistance, and it is widely used for food handling and cutlery among many other applications.Type 304 can be easily roll-formed or bent, and its excellent corrosion resistance and weldability make it one of the most popular grades. Type 316 is a high corrosion resistance alloy, providing greater resistance to pitting-type corrosion. Typical uses for Type 316 include marine, chemical, paper, textile, and food service applications, such as a stainless steel back splash.

Contacter maintenant

304 (UNS S30400, 1.4301) stainless steel is a universal stainless steel, it is widely used to make equipment and machine parts that require good comprehensive performance. In order to maintain the inherent corrosion resistance of stainless steel, the steel must contain more than 18% chromium and more than 8% nickel content. 304 stainless steel is a grade of stainless steel produced in accordance with the American ASTM standard.The most important elements in 304 stainless steel are Ni and Cr, but they are not limited to these two elements.

Contacter maintenant

Products DescriptionStainless steel is notable for its corrosion resistance, and it is widely used for food handling and cutlery among many other applications.CommodityHot and cold rolled stainless steel coil/sheet/pipe/stripGrade201,202,301,304,304j1,304l,321,309s,310s,2205,409l,410,410s,420,420j1,420j2,430,439,409l,443,444,etcStandardISO,JIS,ASTM,AS EN,GBsurfaceNO.1 /NO.2D /NO.2B /BA /NO.3 /NO.4 /NO.240 /NO.320 /NO.400 /HL /NO.7/ NO.8,etcThickness0.2-100mm(common:0.2-0.5mm)(Precision Stainless Steel Strip:0.05mm)Width100-2000mmSpecification1000*2000/L,1219*2438/L,1500*3000/L,1500*6000/L

Contacter maintenant

Austenitic stainless steel refers to stainless steel with an austenitic structure at room temperature. When the steel contains about 18% Cr, 8%-25% Ni, and about 0.1% C, it has a stable austenite structure. Austenitic chromium-nickel stainless steel includes the famous 18Cr-8Ni steel and the high Cr-Ni series steel developed by adding Cr and Ni content and adding Mo, Cu, Si, Nb, Ti and other elements on this basis. Austenitic stainless steel is non-magnetic and has high toughness and plasticity, but its strength is low. It is impossible to strengthen it through phase transformation.

Contacter maintenant

409 stainless steel is a ferritic stainless steel commonly used in machinery, construction and other projects. Due to the presence of austenite grains, the mechanical properties are greatly improved.

Contacter maintenant

316 stainless steel chemical composition:C≤0.08, Si≤1.00, Mn≤2.00, P≤0.035, S≤0.03, Ni:10.0-14.0, Cr:16.0-18.5, Mo:2.0-3.0.

Contacter maintenant