Stainless Steel 316 FlangesStainless Steel 316 Flanges are made up of a chromium nickel molybdenum alloy that is used ordinarily in chloride ion corrosion inclined environments. The molybdenum addition makes the cloth corrosion resistant, in particular to the chloride wealthy conditions. There are excessive carbon and low carbon variations of the 316 cloth which is used primarily based on the welding want and longevity of the utility intended.

Contacter maintenant

Pipe flanges connect pipes, valves, pumps and other equipment in a piping system. Flanges are usually welded or screwed into the systems and then joined with bolts. The eight types of pipe flanges are available in round, square and rectangular shapes.Blind FlangesA blind, or blanking, flange is a round plate with no center hold (but with bolt holes) that closes the ends of piping systems.Lap Joint FlangesPiping fitted with lapped pipe or with lap joint stub ends often use lap joint flanges.

Contacter maintenant

Stainless Steel PipeFormWelded and Seamless in Round.ApplicationFluid & Decorative.Size RangeDN15 – DN600.Grades304/304L & 316/316L.321,309S,310S,347H,2205,2507,254SMO, Wall ThicknessSch 10S, 40S & 80S.FittingsButt Weld, Screwed & Socket Flanges (ANSI, Table E & Table D).ProcessingCut-to-length & polishing.The information provided is for standard stock product and does not encapsulate all available combinations.

Contacter maintenant

Stainless Steel 304L FlangesStainless Steel 304L Flanges has a minimum of 18% chromium and 8% nickel. Type SS 304L Blind FLanges(BLRF) has a Carbon maximum is 0.035. Stainless Steel 304L Pipe Flanges is the standard "18/8 stainless" that is commonly found in Industrial Flanges and applications. 304L Stainless Steel Blind Flange is the most versatile and widely used alloy flange. The ultimate tensile strength (UTS) of SS 304L Spectacle Blind Flange is roughly~515 Mpa, 304L having a 0.2% yield strength of~205Mpa.

Contacter maintenant

duplex 2205 flangesDuplex 2205 flanges are made from an austenitic-ferritic stainless steel, which was once designed to supply greater power and corrosion resistance than 300 sequence stainless steels. It helps customers to keep away from stress corrosion cracking that is normally viewed with 316 and 317.

Contacter maintenant

We mainly produce the Carbon and Alloy Steel Flanges, Nickel Alloy Steel Flanges, Stainless Steel Flanges. Here are the main types of the Flanges that we can supply for you.

Contacter maintenant

Ha alloy, duplex stainless-steel 316 304 and different stainless steel substances, the sort of its commercial enterprise is steel plate, steel pipe, round steel, and so on., may be custom designed in keeping with patron name for processing.316 stainless steel, 18CR-12Ni-2.5Mo due to the addition of Mo, so its corrosion resistance, atmospheric corrosion resistance and high temperature strength is particularly good, can be used under harsh conditions; Excellent work hardening (no magnetic).

Contacter maintenant

Product name :316 stainless steel bar, 304 stainless steel bar, 316 stainless steel bar. Grade :0Cr17Ni12Mo2, main material 316, 316L, 310, 310S, 304, 304L, 303 and so on.1, summary: Mo(2~3%), excellent pitting resistance, excellent creep strength at high temperature.2, features :1, cold rolled product appearance gloss is good, beautiful; 2, add Mo, corrosion resistance, especially excellent pitting resistance; 3.

Contacter maintenant

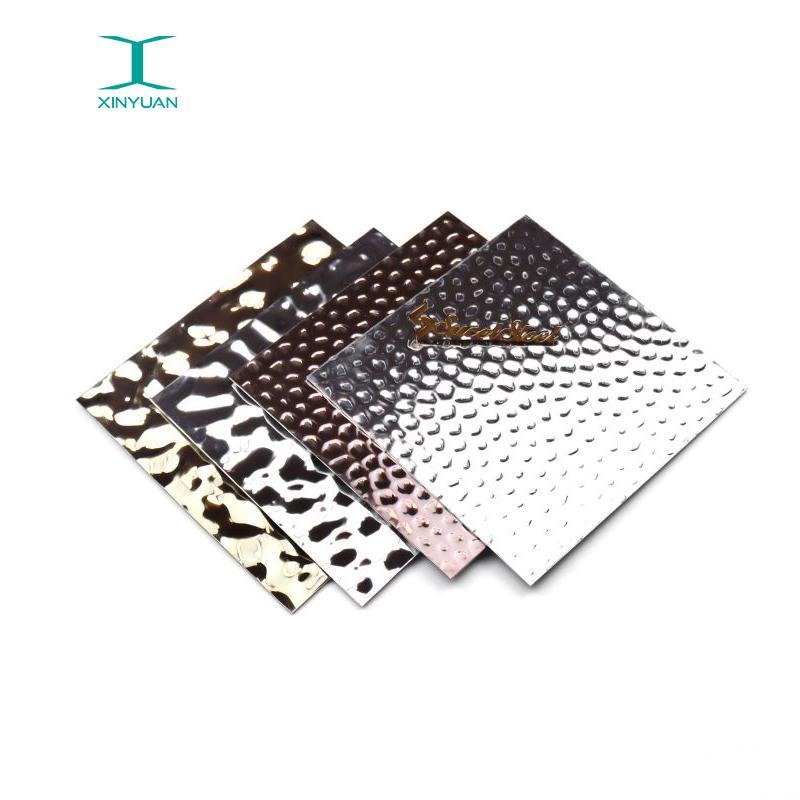

316 304 Patterned Sheet Stainless Steel PlateWe are in presenting a massive kind of stainless steel ornamental sheets inclusive of fashion fashion designer stainless steel sheet, reflect end stainless steel sheet, vibration sheet, hairline sheet, etching sheet, embossing sheet, laser sheet for elevator advent, structure, mechanical engineering packages.Product InformationThickness0.3-4.0mmWidth1000mm/1219mm/1240mm/1250mm/1500mmLengthCustomizedTechniqueCold rolled, Annealing,Slitting, Cutting, Sand blast, Coloring, EmbossingMOQ1 Ton - 25 TonsStandardASTM,AISI,JIS, etc.Material Available200 seri

Contacter maintenant

Popular for its corrosion resistance, stainless steel rod is used in a wide range of applications including the construction of building foundations, bridges, and marine environments.We have black bright surface, and different materials such as 201 304 304L 316 316L 2205 2507 430 420 410 for you to choose.StandardASTM A479,ASTM A276,ASTM A484, ASTM A582, ASME SA276, ASME SA484, GB/T1220, GB4226, etc.Material301, 304, 304L, 309S, 321, 316, 316L, 317, 317L, 310S, 201,202321, 329, 347, 347H 20

Contacter maintenant

ASME B16.5 SpecificationsSpecificationASME B16.5 FlangeType Of Industrial flangesBlind Flange/ Slip On Flange/ Weld Neck Flange/ Socket Weld Flanges/ RTJ Flanges/ Lap Joint Flanges/ Threaded/ Reducing FlangesFlanges Manufacturing MaterialStainless Steel, Brass, Bronze, Duplex Steel, Super Duplex, Incoloy, Alloy 20, Copper, Carbon Steel, Nickel Alloys, Tantalum, Cupro-Nickel Inconel, Monel, Titanium, Hastalloy, Alloy Steel.Type Of Pipe Flange MethodsForging/ Casting/ Rolling And CuttingANSI Flange Pressure ClassClass 150/ Class 300/ Class 400/ Class 600/ Class 600/ Class 900/ Class 1500/ Class

Contacter maintenant

Corrosion resistance.316 Stainless Steel is well-suited for building structures in marine or moist environments. The material resists oxidation, which keeps the material stronger and in good condition for longer.Pitting resistance. Unlike other types of stainless steel (such as 304), with 316 stainless steel material, building managers don’t have to worry about the formation of holes or pitting.Heat resistance. Part of the 316’s oxidation resistance stems from its resistance to heat damage.

Contacter maintenant

DescriptionProduct Namestainless steel plateThickness0.3~260mmWidth600mm,1000mm,1219mm,1500mm,1800mm,2000mm,2500mm, 3000mm, 3500mm,etcLength2000mm, 2440mm, 3000mm, 5800mm, 6000mm, etcStandardASTM GB/T JIS4 ASME BS DIN ENMaterial 200 series: 201/202 300series:301/304/304L/305/309S/310S/316/316L/316LN/316Ti/317/317L/347/347H400 series: 405/409/409L/410/420/430/440C/444/4447 600 series: 630/631 duplex stainless steel: 2205/2507/2520 super stainless steel: 904LFeaturehigh hardness and strength/100% recycled/fire resistant/wter proof/anti corrosion/high tempe

Contacter maintenant

Flat welding flanges are suitable for pipeline systems with relatively low pressure levels and no serious pressure fluctuations, vibrations and shocks.

Contacter maintenant

We are in presenting a big sort of chrome steel decorative sheets inclusive of fashion fashion designer chrome steel sheet, reflect end stainless-steel sheet, vibration sheet, hairline sheet, etching sheet, embossing sheet, laser sheet for elevator creation, architecture, mechanical engineering programs.Product InformationFactory sells 304 316 316l 316ti stainless steel patterned plate and sheetProduct name304 316 316l 316ti stainless steel patterned plateStandardJIS, AiSi, ASTM, GB, DIN, ENLength1000*cWidth1000~2000mmCertificationISOTolerance±1%Processing ServiceBending, Welding, Decoiling, P

Contacter maintenant

Stainless Steel 316 TubeStainless Steel 316 Tube is a grade of stainless metal produced in accordance with the American ASTM standard. Stainless Steel 316 Tube is equal to our country's 0Cr17Ni12Mo2 stainless steel. Japan additionally quoted the American title and referred to as it: SUS316.Stainless Steel 316 Tube has right plasticity, toughness, bloodless denaturation, and welding system performance. Stainless Steel 316 Tube has exact excessive temperature power and 316L has terrible excessive temperature performance, however its corrosion resistance is higher than 316.

Contacter maintenant

This austenite crystalline structure is achieved by sufficient additions of the austenite stabilizing elements nickel, manganese and nitrogen. Due to their crystalline structure, austenitic steels are not hardenable by heat treatment and are essentially non-magnetic.There are two subgroups of austenitic stainless steel. 300 series stainless steels achieve their austenitic structure primarily by a nickel addition while 200 series stainless steels substitute manganese and nitrogen for nickel, though there is still a small nickel content.300 series stainless steels are the larger subgroup.

Contacter maintenant

Product DescriptionWhat you are looking for isASTM 304 316 Tube Stainless Steel Seamless Pipe ManufacturerIf you are still suffering from the inconvenience caused by the corrosion and cracking of the pipeline, or you are suffering from the failure to find a suitable stainless steel heat exchanger tube supplier. MaterialStainless Steel 304/304L/316L/347H/310S/309SShapeRound / Square / RectangleProduction StandardsASTM A270, ASTM A269, ASTM A249, ASTM A778, ASTM A789, DIN 11850, EN 10357, EN 10217-7 and so on.Outer Diameter16mm - 2000mm ; Thickness0.8mm - 20 mm ; Length6 Mete

Contacter maintenant

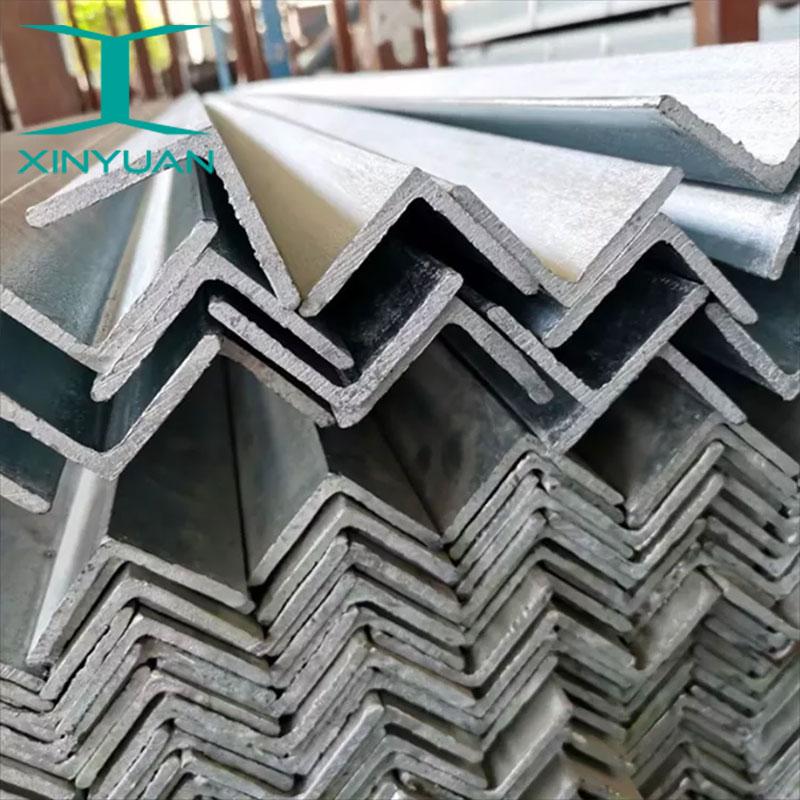

We produce and distribute warm rolled and laser fused chrome steel angles throughout the arena in each imperial and metric sizes. Please pick out the catalog on your area beneath to view a list of available standard size angles.

Contacter maintenant

Grade 316 is also primarily composed of iron, and again contains significant amounts of nickel and chromium¡ª10-14% and 16-18%, respectively¡ªand small amounts of carbon, manganese, molybdenum, and silicon.

Contacter maintenant

Stainless steel is available in many varieties, each of which suits varying applications. Some key properties that make 316 stainless steel the optimal choice for use in structural beams include its:Corrosion resistance.316 stainless steel is well-suited for building structures in marine or moist environments.

Contacter maintenant

316 stainless steel chemical composition:C≤0.08, Si≤1.00, Mn≤2.00, P≤0.035, S≤0.03, Ni:10.0-14.0, Cr:16.0-18.5, Mo:2.0-3.0.

Contacter maintenant

Unlike mild steel the chemistry of stainless steels means the processes and methods for protecting and finishing 316 Grade Stainless Steel are vastly different to mild steels. Most surface finishes for stainless steel will be mechanically (Polishing) or chemically (Passivating) applied. The correct surface finish will have substantial impacts on the performance and appearance of your stainless steel. Product Parameter:StandardASTM A479,ASTM A276,ASTM A484, ASTM A582,ASME SA276, ASME SA484, GB/T1220, GB4226, etc.Material301, 304, 304L, 309S, 321, 316, 316L, 317, 3

Contacter maintenant

316 Stainless Steel Hex Bar316 Stainless Steel Hex Bar exhibits high strength and excellent corrosion resistance including in marine environments. 316 is slightly stronger than 304 stainless and is rated as a marine metal. 316 maintains its properties in cryogenic or high temperatures.

Contacter maintenant